How Does Stainless Steel Improve Corrosion Resistance?

Stainless steel is renowned for its ability to resist rust and corrosion, making it a staple in industries ranging from food processing and medical equipment to construction and marine engineering. Unlike regular carbon steel, which easily rusts when exposed to moisture and oxygen, stainless steel maintains its strength and appearance even in harsh environments. This resistance to corrosion is not a coincidence but a result of its unique composition and the formation of a protective layer on its surface. Understanding how stainless steel achieves this resistance helps explain why it is preferred for applications where durability and hygiene are critical. This guide explores the science behind stainless steel’s corrosion resistance, its key components, and how it performs in different environments.

The Role of Chromium in Stainless Steel

The primary reason stainless steel resists corrosion is its high chromium content. Chromium is a metallic element that reacts with oxygen to form a protective layer on the surface of the steel, which is key to its durability.

- Passive Layer Formation: When stainless steel contains at least 10.5% chromium (the minimum required for corrosion resistance), the chromium reacts with oxygen in the air or water to form a thin, invisible layer called chromium oxide (Cr₂O₃). This layer is often referred to as the “passive layer” because it passivates the steel, meaning it stops further reaction with the environment.

- Self-Healing Property: If the passive layer is scratched or damaged (e.g., by a cut or abrasion), the chromium in the steel immediately reacts with oxygen again to repair the layer. As long as there is enough oxygen and chromium present, the passive layer reforms, preventing rust from spreading. This self-healing ability is unique to stainless steel and ensures long-term protection.

- Higher Chromium for More Resistance: Stainless steel grades with higher chromium content (e.g., 18% or more) form a thicker, more stable passive layer. These grades are used in highly corrosive environments, such as coastal areas with salt spray or chemical processing plants, where extra protection is needed.

The chromium-based passive layer is the foundation of stainless steel’s corrosion resistance, making it far more durable than carbon steel in wet or harsh conditions.

Other Alloying Elements That Enhance Resistance

While chromium is the main contributor, other alloying elements in stainless steel further improve its corrosion resistance and performance in specific environments.

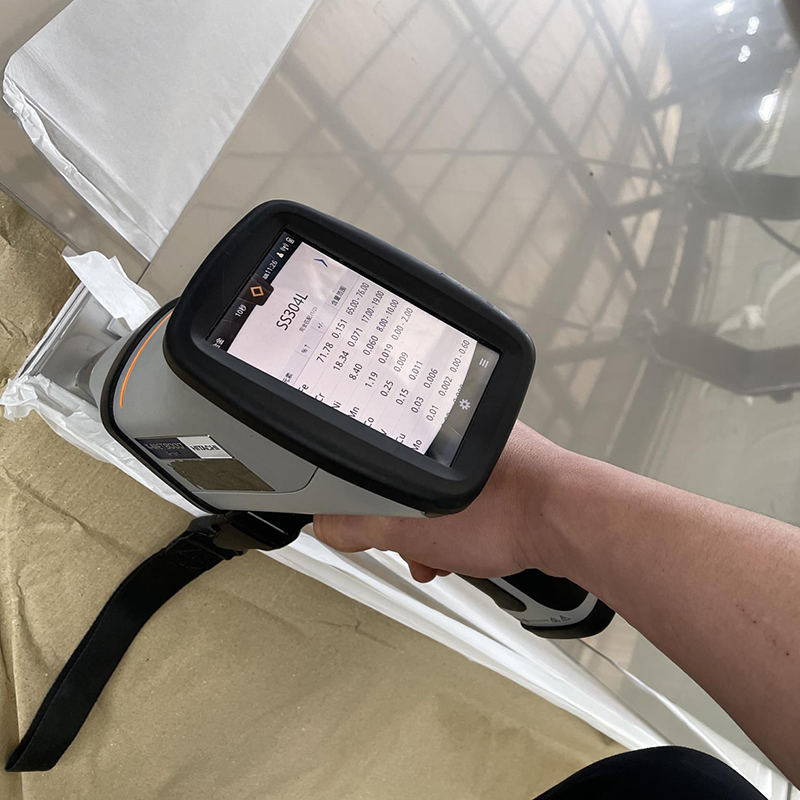

- Nickel: Adding nickel (common in austenitic stainless steel grades like 304 and 316) stabilizes the steel’s structure, making it more ductile and easier to form. Nickel also enhances the passive layer’s ability to resist corrosion in acidic or alkaline environments, making these grades suitable for food processing equipment or chemical tanks.

- Molybdenum: Molybdenum is added to stainless steel (e.g., grade 316) to improve resistance to pitting corrosion, a type of localized damage caused by chloride ions in saltwater, sweat, or industrial chemicals. This makes molybdenum-containing stainless steel ideal for marine applications, coastal structures, or medical devices that come into contact with bodily fluids.

- Titanium or Niobium: These elements prevent sensitization, a process where chromium carbides form at grain boundaries during welding, reducing chromium in the surrounding area and weakening corrosion resistance. Stainless steel grades with titanium or niobium (e.g., 321) are often used in welded structures like pipes or tanks, ensuring the passive layer remains intact even after high-temperature processing.

- Nitrogen: Nitrogen increases the strength of stainless steel and enhances its resistance to pitting and crevice corrosion, often used in high-strength grades for structural applications in corrosive environments.

These alloying elements work with chromium to tailor stainless steel’s corrosion resistance to specific needs, from everyday use to extreme industrial conditions.

Resistance to Different Types of Corrosion

Stainless steel’s passive layer and alloying elements protect it against various forms of corrosion, which are common in different environments:

- General Corrosion: This is uniform rusting across a material’s surface, typical of carbon steel exposed to moisture. Stainless steel’s passive layer prevents general corrosion, even in wet environments like kitchens, bathrooms, or outdoor structures.

- Pitting Corrosion: Small holes (pits) form when chloride ions (from salt, bleach, or seawater) break through the passive layer. Molybdenum-containing stainless steel (grade 316) resists pitting, making it better than grade 304 for coastal or poolside applications.

- Crevice Corrosion: This occurs in tight spaces (crevices) where oxygen is limited, such as under bolts, gaskets, or dirt. The passive layer cannot reform without oxygen, allowing corrosion to start. Stainless steel with a higher chromium and molybdenum content minimizes this risk, making it suitable for machinery with tight joints.

- Stress Corrosion Cracking: This happens when a material is under stress (e.g., from welding or bending) and exposed to corrosive environments. Austenitic stainless steel grades (like 304 and 316) are more resistant to stress corrosion cracking than other types, making them ideal for pressure vessels or structural components under load.

By resisting these corrosion types, stainless steel maintains its strength and appearance, reducing maintenance and replacement costs in diverse applications.

Hygiene and Easy Maintenance

Stainless steel’s corrosion resistance also contributes to its hygiene and ease of maintenance, making it popular in industries where cleanliness is critical.

- Non-Porous Surface: The passive layer creates a smooth, non-porous surface that resists the growth of bacteria, mold, and mildew. This is essential in food processing, hospitals, and pharmaceutical facilities, where hygiene prevents contamination.

- Easy Cleaning: Stainless steel can be cleaned with simple detergents or sanitizers without damaging the passive layer. Unlike materials that corrode when exposed to cleaning chemicals, stainless steel retains its resistance, ensuring long-term hygiene.

- Resistance to Chemicals: Many stainless steel grades resist acids, alkalis, and cleaning agents, making them suitable for laboratories, commercial kitchens, and industrial settings where exposure to chemicals is common.

This combination of corrosion resistance and hygiene makes stainless steel indispensable in environments where cleanliness and durability go hand in hand.

Longevity and Cost-Effectiveness

While stainless steel is more expensive upfront than carbon steel, its corrosion resistance ensures long-term cost savings, making it a cost-effective choice in the long run.

- Extended Lifespan: Stainless steel components last decades without rusting or deteriorating, even in harsh environments. For example, stainless steel outdoor railings or marine hardware can withstand saltwater and weather for 20–30 years, compared to 5–10 years for painted carbon steel.

- Reduced Maintenance: Unlike carbon steel, which requires regular painting, coating, or repairs to prevent rust, stainless steel needs minimal maintenance. This saves time, labor, and materials over the product’s lifespan.

- Lower Replacement Costs: Because stainless steel resists corrosion, there is less need for frequent replacements. This is especially valuable in hard-to-reach areas, such as roof structures or underwater pipes, where replacing corroded parts is expensive and disruptive.

The long-term durability of stainless steel justifies its initial cost, making it a smart investment for both industrial and consumer applications.

FAQ

What is the minimum chromium content in stainless steel for corrosion resistance?

Stainless steel requires at least 10.5% chromium by weight to form the protective passive layer needed for corrosion resistance. Higher chromium content (18% or more) provides enhanced protection.

Why is grade 316 stainless steel more corrosion-resistant than grade 304?

Grade 316 contains molybdenum, which improves resistance to pitting and crevice corrosion caused by chloride ions (e.g., saltwater). Grade 304 lacks molybdenum, making it less suitable for highly corrosive environments.

Can stainless steel rust?

Stainless steel can rust if the passive layer is damaged and cannot reform—for example, in low-oxygen environments or when exposed to high levels of chlorides without enough molybdenum. Proper maintenance and choosing the right grade reduce this risk.

Is stainless steel suitable for outdoor use?

Yes. Stainless steel grades like 304 work well for most outdoor environments, while grade 316 is better for coastal areas or regions with high humidity and salt exposure.

How do you maintain stainless steel’s corrosion resistance?

Clean regularly to remove dirt, salt, or chemicals that can damage the passive layer. Avoid abrasive cleaners that scratch the surface, and ensure proper ventilation in enclosed spaces to allow the passive layer to reform if damaged.

Hot News

Hot News