In the ever-evolving landscape of industrial materials, titanium sheets have emerged as a game-changing solution that combines exceptional strength with remarkable versatility. These advanced metal components have revolutionized numerous industries, from aerospace and medical applications to architectural designs and consumer products. As manufacturers and engineers seek materials that can meet increasingly demanding specifications, titanium sheets continue to demonstrate their superior capabilities across diverse applications.

The unique properties of titanium sheets have made them indispensable in high-performance environments where traditional materials fall short. Their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility have opened new possibilities in design and engineering. Understanding these advantages is crucial for professionals looking to optimize their material selection and enhance their products' performance.

Titanium sheets exhibit an impressive strength-to-weight ratio that surpasses many conventional metals. While maintaining a density approximately 40% lower than steel, they offer comparable or superior strength characteristics. This unique combination makes titanium sheets particularly valuable in applications where weight reduction is crucial without compromising structural integrity.

The mechanical properties of titanium sheets allow engineers to design lighter components while maintaining or improving performance standards. In aerospace applications, this translates to fuel efficiency and increased payload capacity. For medical implants, the reduced weight ensures better patient comfort while providing the necessary structural support.

One of the most remarkable attributes of titanium sheets is their natural resistance to corrosion. The material forms a stable, protective oxide layer when exposed to air or moisture, preventing further oxidation and degradation. This self-protecting characteristic makes titanium sheets ideal for marine environments, chemical processing equipment, and outdoor architectural applications.

The corrosion resistance of titanium sheets extends to various aggressive environments, including saltwater, acids, and industrial chemicals. This durability translates to reduced maintenance requirements and longer service life, making them a cost-effective choice despite higher initial investment.

The aerospace industry has been at the forefront of titanium sheet utilization, incorporating these materials into aircraft structures, engine components, and specialized parts. The combination of high strength, low weight, and excellent fatigue resistance makes titanium sheets essential for modern aircraft design and performance optimization.

Defense applications benefit from the material's ability to withstand extreme conditions while maintaining structural integrity. From military aircraft to naval vessels, titanium sheets provide the durability and reliability required in mission-critical situations.

The biocompatibility of titanium sheets has revolutionized medical device manufacturing and surgical implant design. The material's ability to integrate with human tissue while resisting corrosion in biological environments makes it the preferred choice for various medical applications.

From surgical instruments to prosthetic components, titanium sheets offer the perfect balance of strength, lightness, and biocompatibility. The material's low thermal conductivity also provides additional comfort for patients with implanted devices.

Titanium sheets contribute to environmental sustainability through their longevity and recyclability. The extended service life reduces the need for frequent replacements, while the material's ability to be fully recycled minimizes environmental impact. The energy-intensive initial production is offset by the material's durability and reusability.

The growing focus on sustainable manufacturing practices has highlighted the importance of materials that offer both performance and environmental responsibility. Titanium sheets meet these criteria by providing long-term value and reducing waste through their recyclability.

While the initial cost of titanium sheets may be higher than alternative materials, the long-term economic benefits often justify the investment. Reduced maintenance requirements, extended service life, and improved performance contribute to significant cost savings over time.

When considering lifecycle costs, titanium sheets often emerge as the more economical choice, particularly in applications where material failure or replacement would result in substantial operational disruptions or safety concerns.

Modern manufacturing techniques have enhanced the processability of titanium sheets, making them suitable for various fabrication methods. Advanced forming, welding, and machining capabilities allow for complex shapes and precise specifications to be achieved while maintaining the material's inherent properties.

The ability to work with titanium sheets using conventional equipment, albeit with specific modifications and expertise, has made them more accessible to manufacturers across different industries. This manufacturing flexibility contributes to their growing adoption in diverse applications.

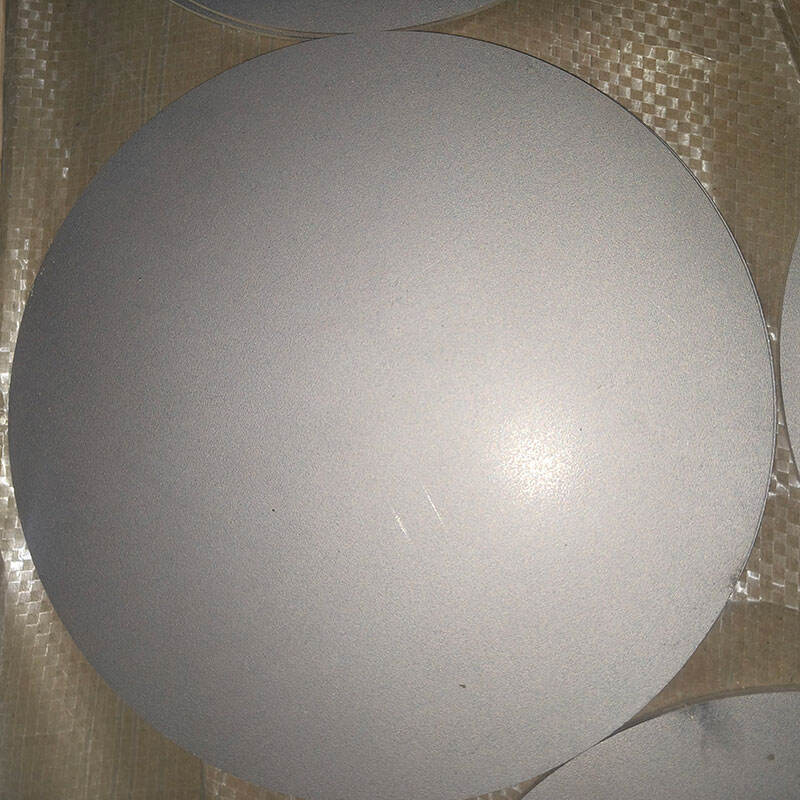

Titanium sheets can be treated with various surface finishing techniques to enhance their properties further. From anodizing for decorative purposes to specialized coatings for improved wear resistance, these treatments expand the material's functionality and aesthetic appeal.

The natural oxide layer can be modified through controlled processes to achieve specific surface characteristics, making titanium sheets adaptable to various design requirements and environmental conditions.

Titanium sheets stand out due to their exceptional combination of high strength, low weight, and superior corrosion resistance. Unlike other metals, they offer a unique balance of properties that includes biocompatibility, heat resistance, and the ability to form a protective oxide layer naturally.

When properly specified and maintained, titanium sheets can last several decades or even longer. Their natural corrosion resistance and structural stability contribute to an extensive service life that often exceeds that of alternative materials, particularly in demanding environments.

The long-term value of titanium sheets often justifies their higher initial cost. Factors such as reduced maintenance requirements, extended service life, improved performance, and lower lifecycle costs typically result in significant cost savings over time, especially in critical applications where reliability and durability are essential.

Hot News

Hot News2025-01-03

2024-10-23

2024-11-15