hete Gevou Rolkoil

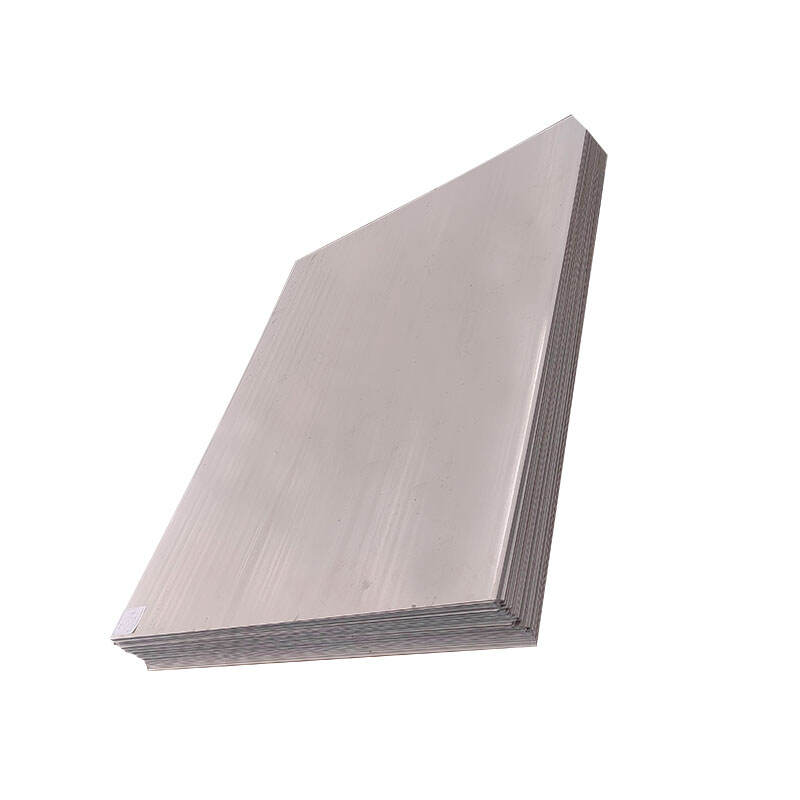

Warmgewalste spoel verteenwoordig 'n fundamentele staalproduk wat vervaardig word deur 'n hoë-temperatuur-walseringsproses, gewoonlik bo 1700°F. Hierdie vervaardigingsmetode behels die verhitting van dik staalskywe tot ekstreme temperature voordat dit deur 'n reeks rollers gevoer word wat progresjief hul dikte verminder om die gewenste dimensies te skep. Die proses lewer 'n produk wat bestendige materiaaleienskappe regdeur sy struktuur vertoon, wat dit ideaal maak vir verskeie industriële toepassings. Warmgewalste spoel het 'n kenmerkende donkergrys oppervlak met effens afgeronde rande en 'n skubbige afwerking, wat 'n direkte gevolg is van die oksiedvorming tydens die verhittings- en walsproses. Die materiaal se veelsydigheid word aangetoon deur sy wye verskeidenheid dikte-opsies, gewoonlik tussen 1,2 mm en 25 mm, en wydtevariasies wat tot 2000 mm kan strek. Hierdie spoel dien as noodsaaklike grondstowwe in verskeie nywe, insluitend konstruksie, motorvervaardiging, industriële toerustingproduksie en infrastruktuurontwikkeling. Die produk se meganiese eienskappe, soos uitstekende vervormbaarheid en lasbaarheid, maak dit veral geskik vir toepassings wat strukturele sterkte en duursaamheid vereis. Daarbenewens bied warmgewalste spoel koste-effektiewe oplossings vir grootskaalse vervaardigingsoperasies as gevolg van sy doeltreffende produksieproses en minimale nabehandelingvereistes.