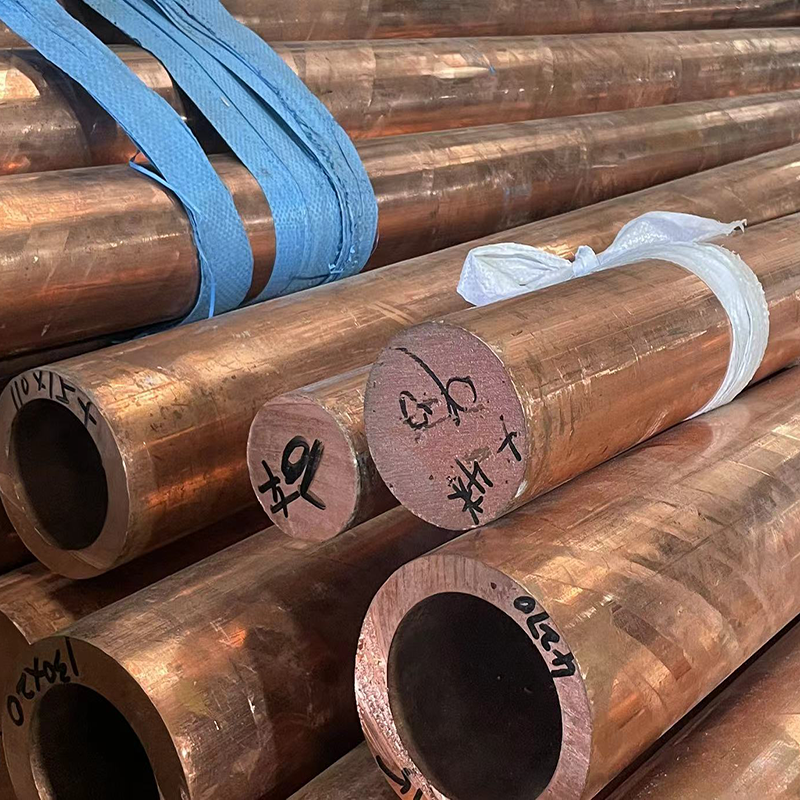

2507 round bar

The 2507 round bar is a premium grade super duplex stainless steel product that combines exceptional strength with superior corrosion resistance. This high-performance material consists of a balanced microstructure of approximately 50% austenite and 50% ferrite, which contributes to its remarkable mechanical properties. With a high chromium content of about 25% and molybdenum at 4%, the 2507 round bar demonstrates outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking. Its nitrogen content enhances both strength and corrosion resistance, making it particularly suitable for demanding marine and chemical processing applications. The material exhibits excellent mechanical properties, including high yield strength typically exceeding 550 MPa and ultimate tensile strength above 800 MPa. These characteristics, combined with good ductility and impact toughness, make it an ideal choice for critical components in offshore platforms, desalination plants, and chemical processing equipment. The 2507 round bar maintains its structural integrity in temperatures ranging from -50°C to 300°C, ensuring reliable performance in various operational conditions.