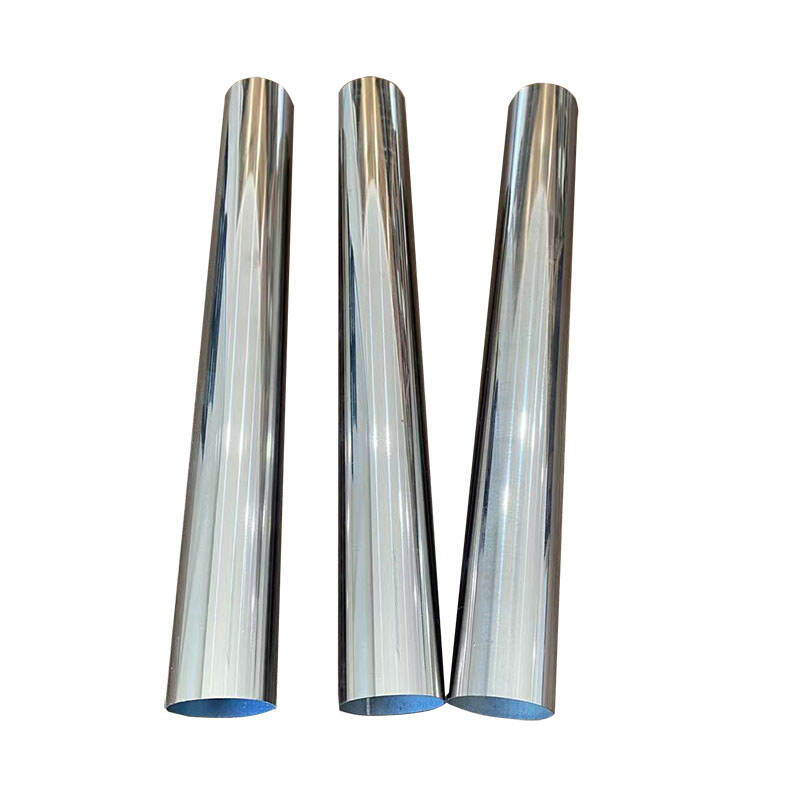

310 stainless round bar

310 stainless round bar represents a premium grade austenitic stainless steel product that offers exceptional resistance to high temperatures and corrosive environments. This versatile material combines superior mechanical properties with outstanding heat resistance, making it ideal for applications requiring sustained performance at elevated temperatures up to 1150°C. The round bar format provides excellent machinability and fabrication capabilities, allowing for precise manufacturing of various components. Its unique chemical composition, featuring high chromium and nickel content, ensures remarkable resistance to oxidation, carburization, and sulfidation. The material demonstrates exceptional structural stability and maintains its strength even during prolonged exposure to extreme conditions. These round bars are manufactured through precise hot rolling and heat treatment processes, ensuring consistent quality throughout the material. The product is widely utilized in heat-treating equipment, furnace parts, chemical processing equipment, and various high-temperature applications in petrochemical industries. Its superior corrosion resistance makes it particularly valuable in marine environments and chemical processing facilities where exposure to aggressive media is common.