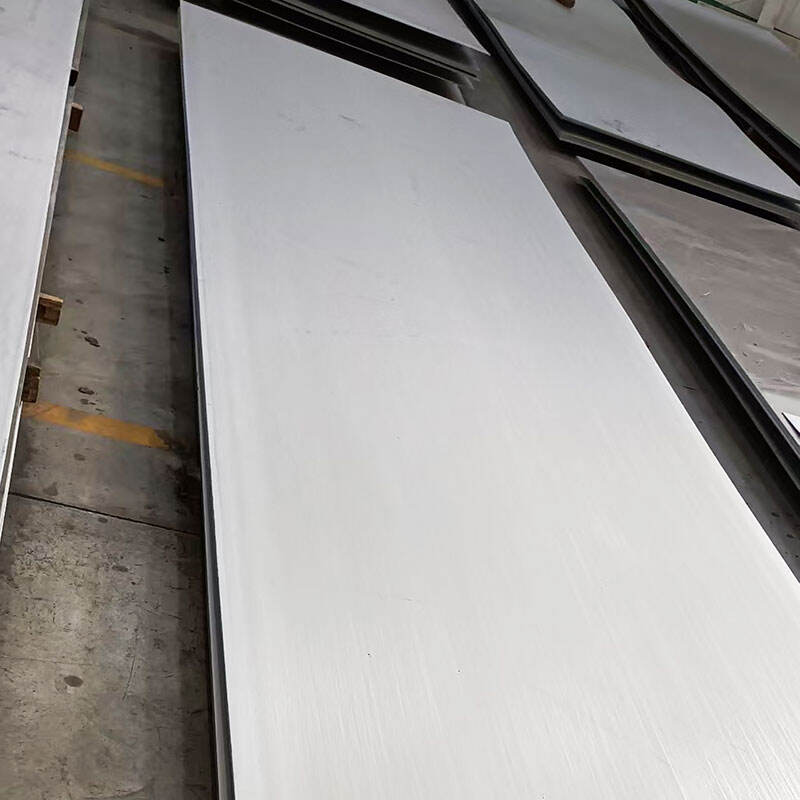

316 stainless steel tube

316 stainless steel tube represents a premium grade of austenitic stainless steel, engineered for superior corrosion resistance and exceptional durability. This versatile material contains higher levels of nickel and molybdenum compared to other stainless steel grades, making it particularly resistant to chlorides and harsh chemical environments. The tube's composition typically includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, creating a robust structure that maintains its integrity even under extreme conditions. These tubes are widely utilized in marine applications, chemical processing facilities, pharmaceutical manufacturing, and food processing industries where maintaining material purity is crucial. The seamless construction ensures consistent performance throughout the tube's length, while the smooth surface finish minimizes the risk of bacterial growth and product contamination. Available in various dimensions and wall thicknesses, 316 stainless steel tubes can be customized to meet specific application requirements, offering flexibility in design and implementation. The material's excellent mechanical properties, including high tensile strength and impressive ductility, make it suitable for both high-pressure and high-temperature applications, maintaining structural integrity in temperatures ranging from cryogenic to 870°C.