inconel 600 sheet

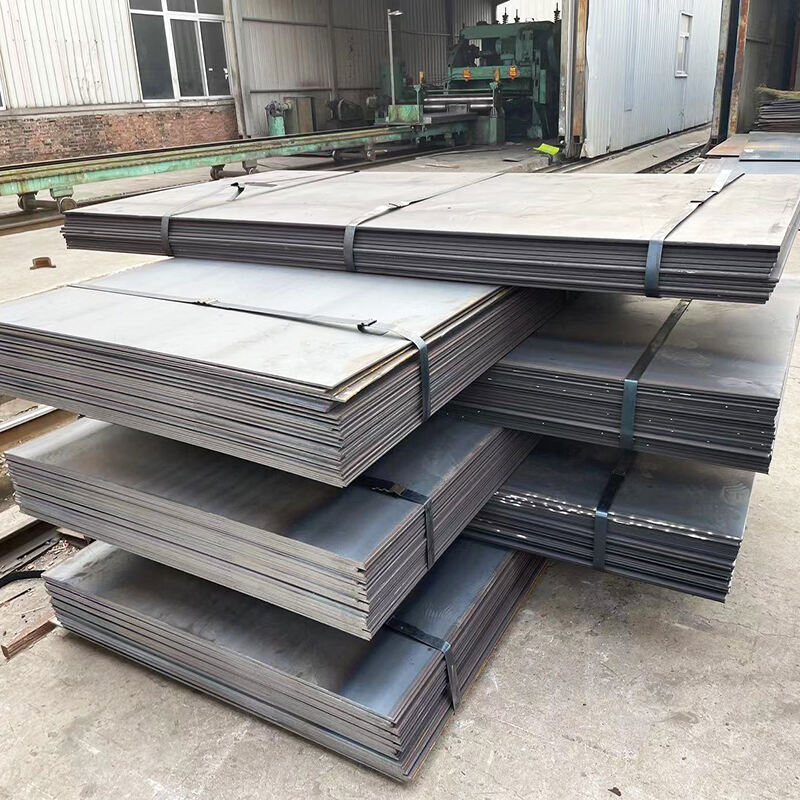

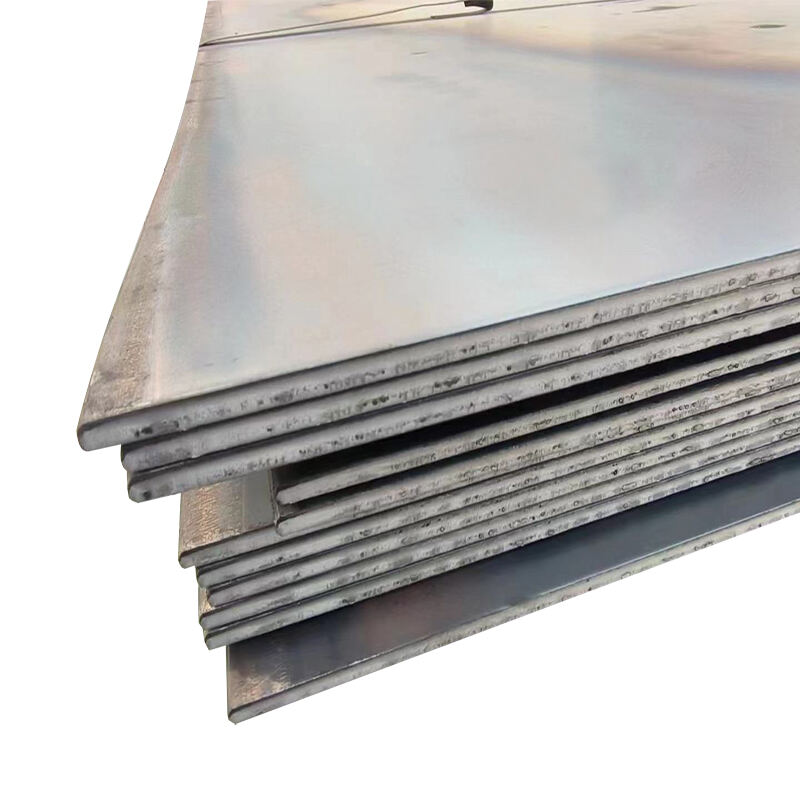

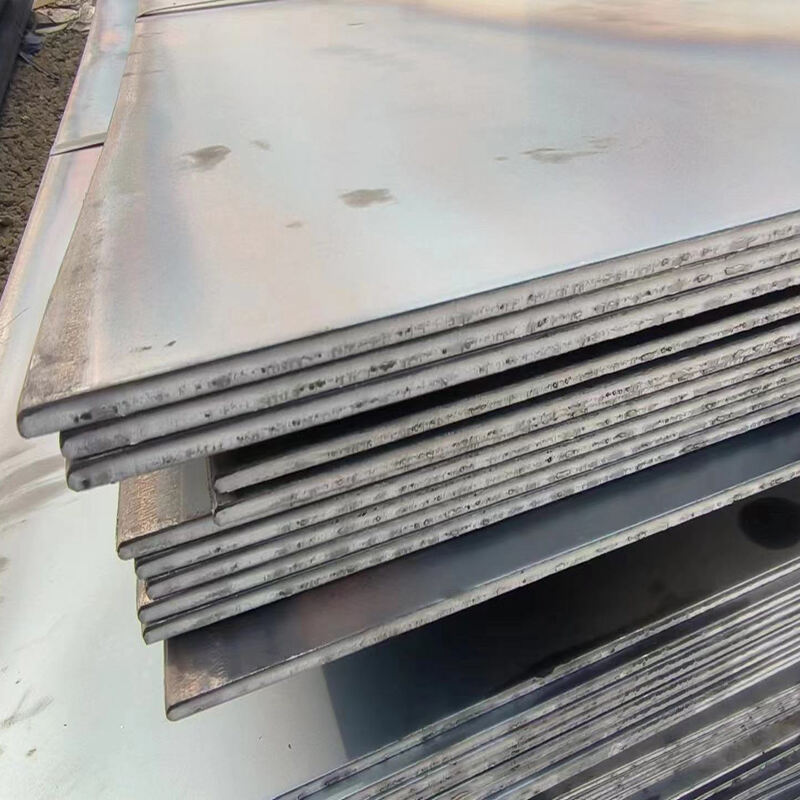

Inconel 600 sheet is a high-performance nickel-chromium alloy that demonstrates exceptional resistance to corrosion and heat in extreme environments. This versatile material contains approximately 72% nickel, 14-17% chromium, and 6-10% iron, creating a robust composition that maintains its structural integrity across a wide temperature range. The sheet's remarkable resistance to oxidation and carburization makes it ideal for applications involving temperatures up to 2,000°F (1,093°C). In industrial settings, Inconel 600 sheet serves as a critical component in chemical processing equipment, nuclear power plants, and aerospace applications. Its excellent mechanical properties, including high tensile strength and impressive ductility, ensure reliable performance under severe operating conditions. The material's resistance to chloride-ion stress-corrosion cracking, coupled with its ability to maintain strength without sensitization in the critical temperature range, makes it particularly valuable in marine environments and high-temperature processing applications. Furthermore, its exceptional welding characteristics and formability allow for versatile manufacturing processes, enabling the creation of complex components while maintaining structural integrity.