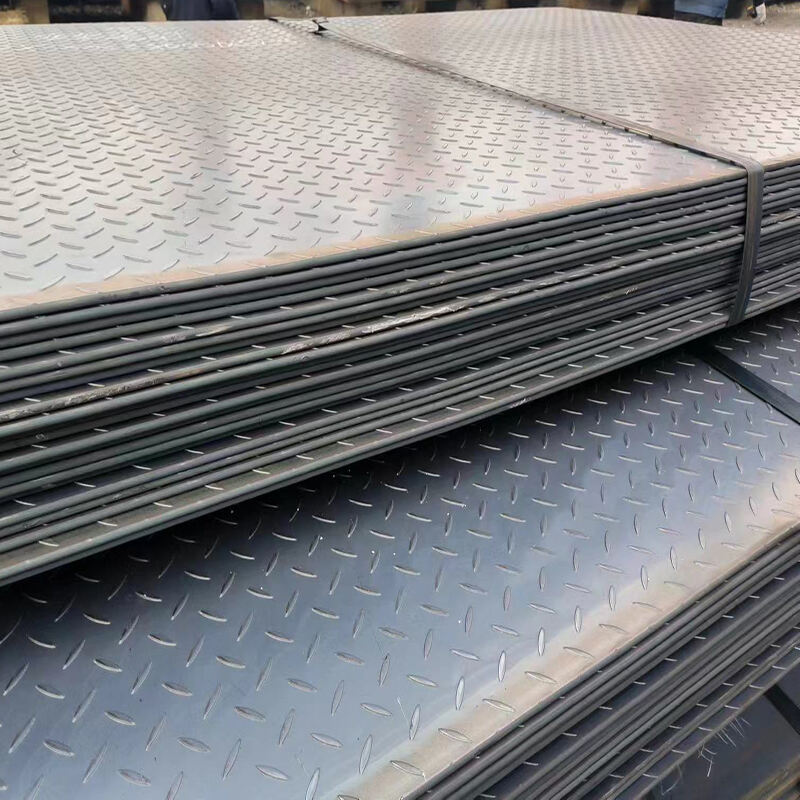

iron angle bar

The iron angle bar, a fundamental component in construction and manufacturing, represents a versatile structural element characterized by its L-shaped cross-section. This essential building material consists of two perpendicular legs or flanges that form a 90-degree angle, providing exceptional structural support and stability. Manufactured through hot-rolling processes, iron angle bars are available in various sizes, thicknesses, and lengths to accommodate diverse project requirements. Their primary function revolves around providing reinforcement and support in construction applications, ranging from building frameworks to industrial equipment assembly. The material composition typically includes high-quality steel or iron, ensuring durability and resistance to environmental factors. These angle bars excel in load-bearing applications, offering superior strength-to-weight ratios and remarkable versatility in both horizontal and vertical installations. Their standardized design facilitates easy integration with other construction materials and enables straightforward installation processes. The iron angle bar's structural integrity makes it particularly valuable in projects requiring robust support systems, such as building frames, roof trusses, and equipment mounting brackets. Additionally, their corrosion-resistant properties, when properly treated, ensure longevity and minimal maintenance requirements throughout their service life.