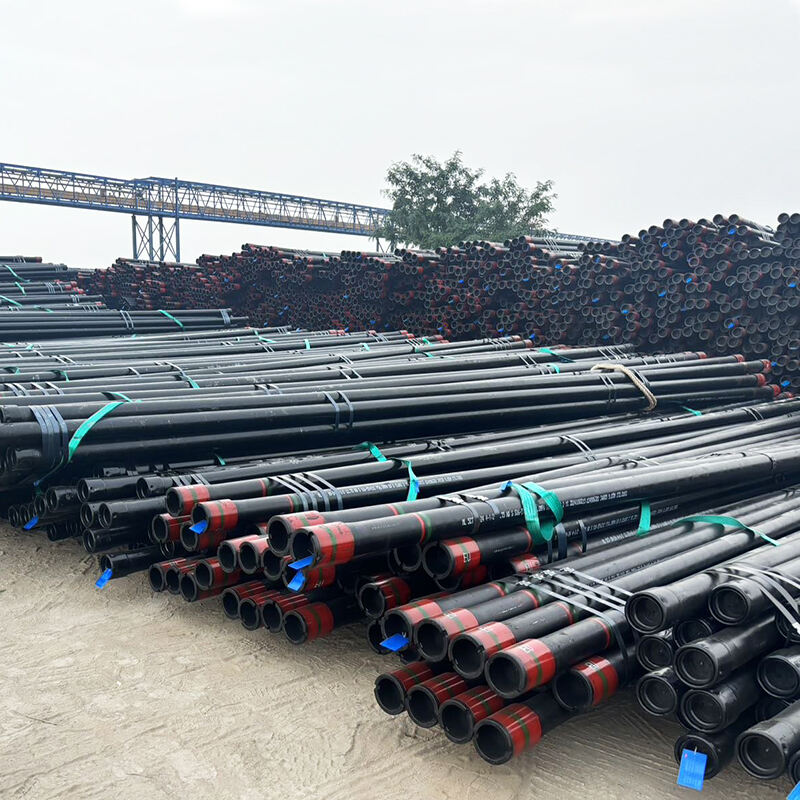

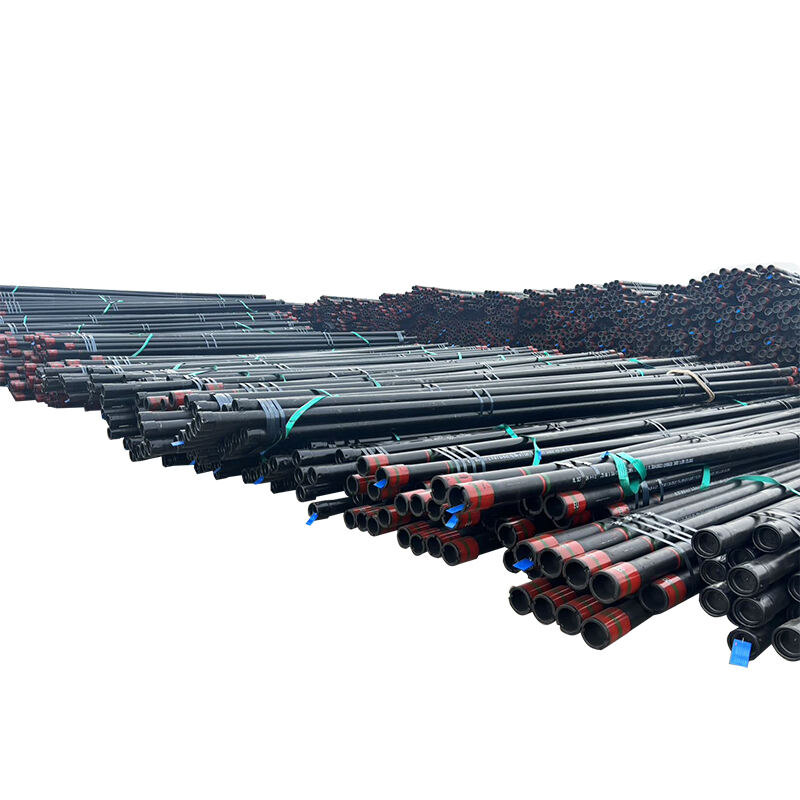

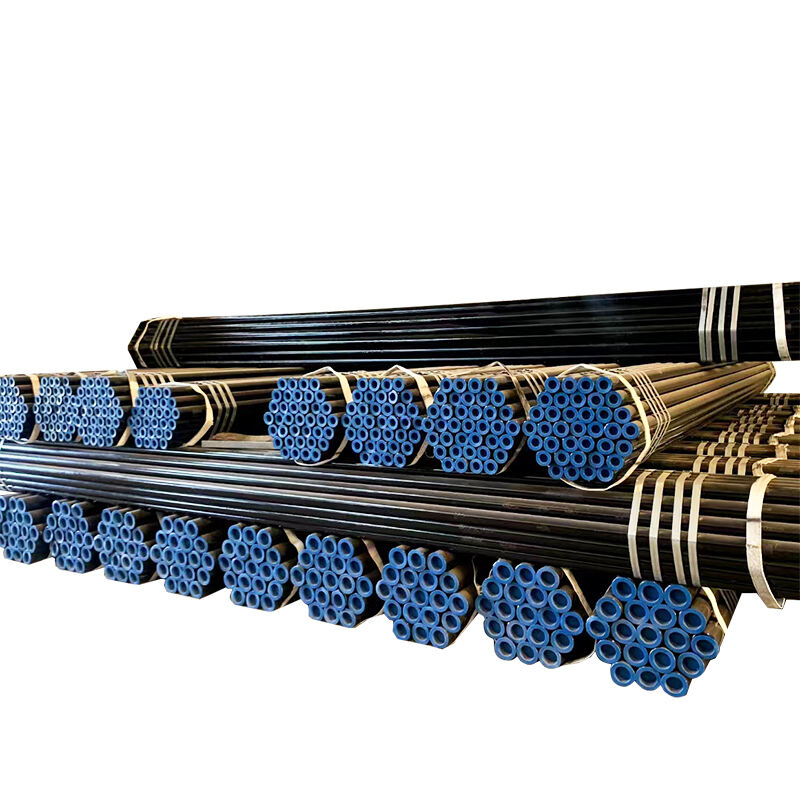

mild steel tube

Mild steel tube represents a versatile and essential component in modern construction and manufacturing industries. This fundamental building material is crafted from low-carbon steel, typically containing carbon content between 0.05% and 0.25%, making it highly malleable and adaptable to various applications. The manufacturing process involves careful heating and rolling of steel billets into seamless or welded tubes, ensuring consistent quality and structural integrity. These tubes come in various dimensions, from small-diameter pipes suitable for residential plumbing to large-scale industrial applications. The material's inherent properties include excellent weldability, superior machinability, and remarkable formability, making it an ideal choice for both structural and non-structural applications. Mild steel tubes demonstrate exceptional durability under normal environmental conditions and can be easily protected against corrosion through various surface treatments. Their widespread use spans across multiple sectors, including construction, automotive manufacturing, furniture making, and agricultural equipment. The tubes can withstand significant mechanical stress and are particularly valued for their ability to maintain structural integrity under varying load conditions. Additionally, their cost-effectiveness and readily available nature make them a practical choice for numerous industrial and commercial applications.