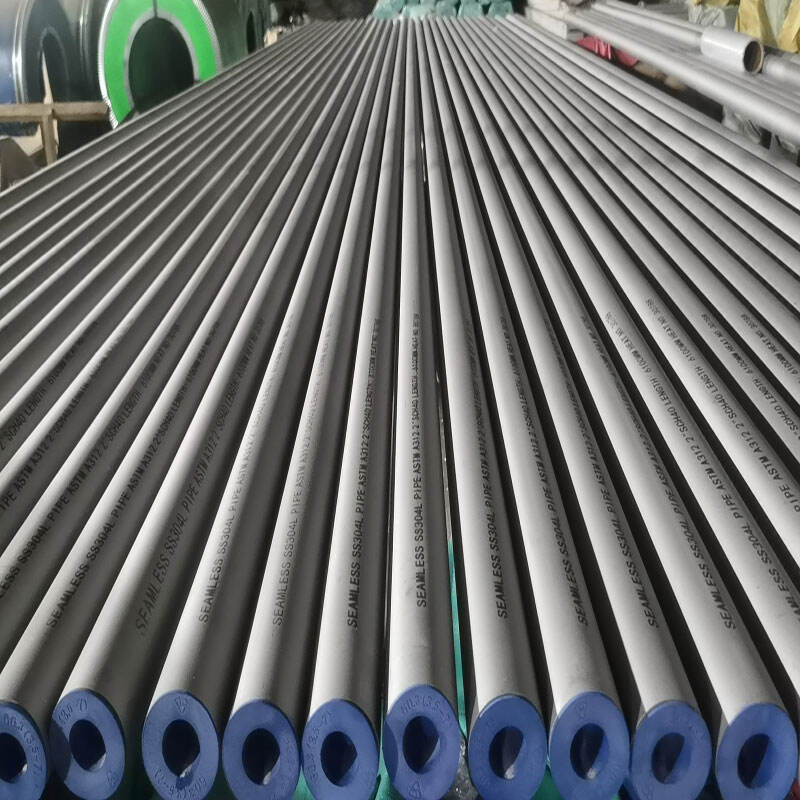

seamless stainless steel pipe

Seamless stainless steel pipes represent a pinnacle of industrial engineering, manufactured through an advanced process that creates a continuous, joint-free tube structure. These pipes are produced by hot forming solid billets into hollow shells and further processing them through multiple stages of hot and cold working to achieve the desired dimensions. The absence of welded joints eliminates potential weak points, making these pipes exceptionally reliable for high-pressure and high-temperature applications. The stainless steel composition provides superior corrosion resistance, while the seamless construction ensures uniform strength throughout the entire length. These pipes find extensive use in critical industries including oil and gas transportation, chemical processing, nuclear power generation, and pharmaceutical manufacturing. The manufacturing process involves sophisticated quality control measures, ensuring consistent wall thickness, precise dimensional accuracy, and optimal mechanical properties. With their ability to withstand extreme conditions and maintain structural integrity, seamless stainless steel pipes have become indispensable in modern industrial infrastructure.