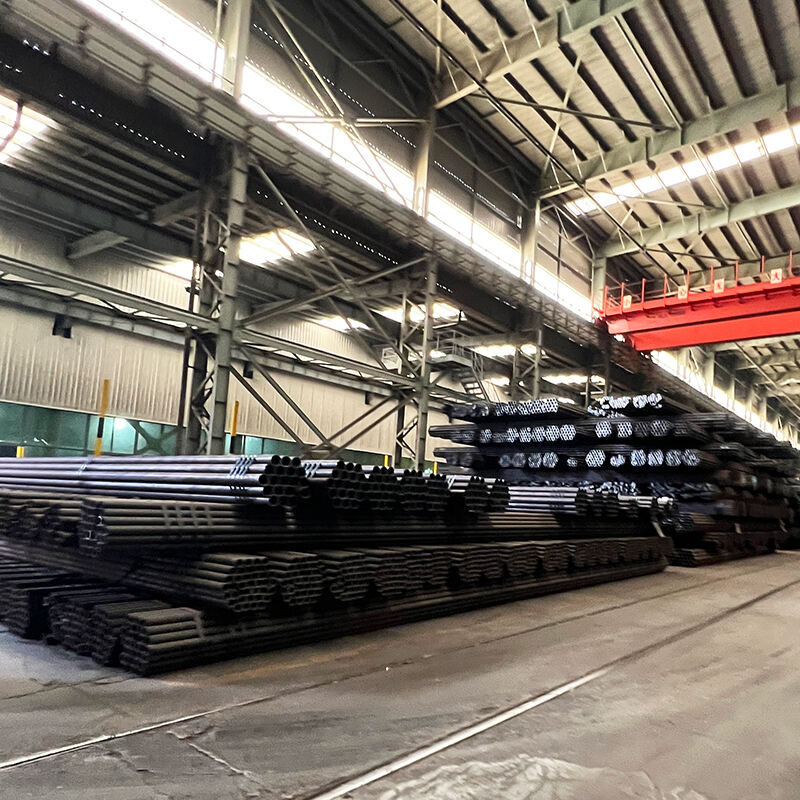

smls pipe

Seamless (SMLS) pipes represent a revolutionary advancement in pipeline technology, manufactured through a sophisticated process that creates tubes without any welded seams. These pipes are formed by hot-working steel or other metals into a seamless cylinder, ensuring uniform strength throughout the entire structure. The manufacturing process involves heating a solid steel billet and piercing it to create a hollow shell, which is then precision-rolled and sized to meet exact specifications. SMLS pipes are engineered to withstand extreme pressures, temperatures, and corrosive environments, making them essential in critical applications across various industries. Their seamless construction eliminates the weak points typically associated with welded joints, resulting in superior mechanical properties and enhanced reliability. These pipes are extensively used in oil and gas transportation, chemical processing, power generation, and construction industries, where safety and structural integrity are paramount. The absence of seams also means reduced maintenance requirements and a longer operational lifespan, contributing to their cost-effectiveness over time. SMLS pipes are available in various grades, sizes, and wall thicknesses to accommodate different operational requirements and industry standards.