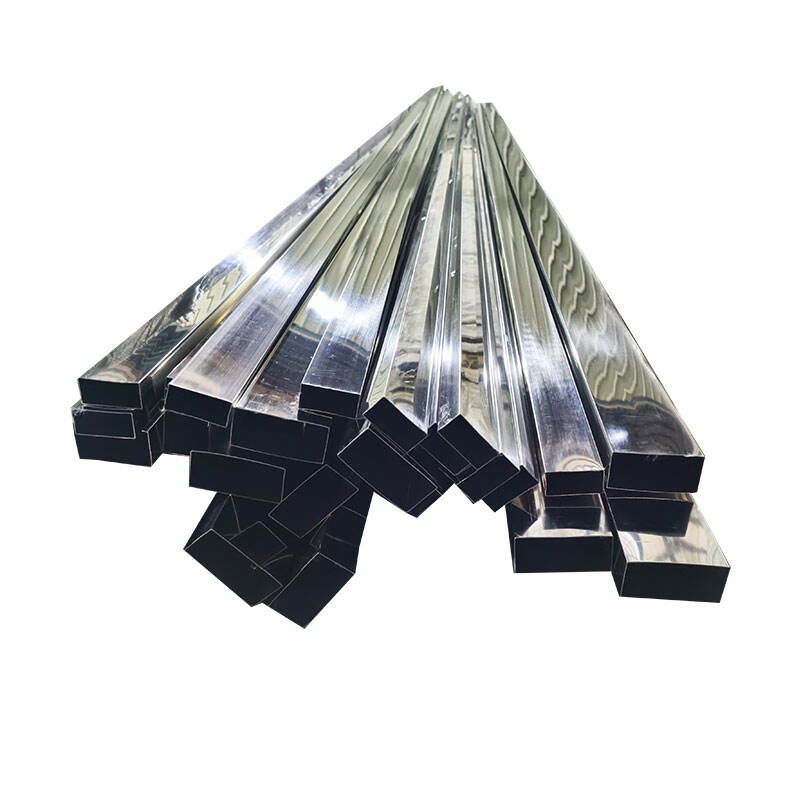

ss 316 coil

The SS 316 coil represents a pinnacle of engineering excellence in stainless steel manufacturing, characterized by its exceptional corrosion resistance and durability. This premium-grade austenitic stainless steel coil combines chromium, nickel, and molybdenum in a precisely controlled composition, resulting in superior performance across diverse applications. The coil's molecular structure ensures remarkable resistance to chemical corrosion, particularly in chloride environments, while maintaining structural integrity at both elevated temperatures and cryogenic conditions. In industrial applications, SS 316 coils serve critical roles in chemical processing, marine environments, and pharmaceutical manufacturing. The material's non-magnetic properties and low carbon content make it particularly valuable in scenarios requiring minimal magnetic interference. Its smooth surface finish reduces bacterial growth potential, making it ideal for medical and food processing equipment. The coil's excellent formability allows for precise shaping without compromising its protective properties, while its weldability ensures reliable joining in complex assemblies. These characteristics, combined with its long service life and minimal maintenance requirements, make the SS 316 coil a cost-effective solution for demanding industrial applications.