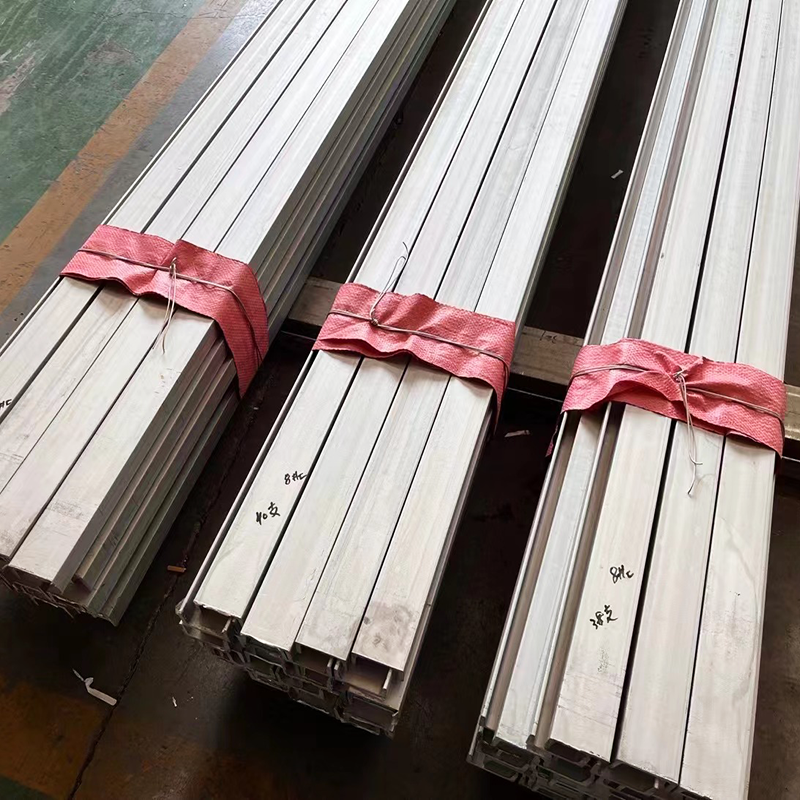

steel bar

Steel bars are fundamental components in construction and manufacturing, serving as essential structural elements that provide strength and stability across various applications. These versatile metal products are manufactured through carefully controlled processes, including hot rolling and heat treatment, to achieve specific mechanical properties. Steel bars come in various grades, shapes, and sizes, offering different levels of tensile strength, durability, and corrosion resistance. They play a crucial role in reinforcing concrete structures, serving as the backbone of modern construction projects from residential buildings to massive infrastructure developments. The manufacturing process ensures precise dimensional accuracy and consistent material properties throughout the bar length, making them reliable for critical load-bearing applications. Steel bars are also extensively used in mechanical engineering applications, serving as raw materials for machining parts, tools, and various industrial components. Their versatility extends to applications in the automotive industry, heavy machinery manufacturing, and general fabrication work. The standardized production methods and rigorous quality control measures ensure that steel bars meet international specifications and standards, making them trusted components in structural and mechanical applications worldwide.