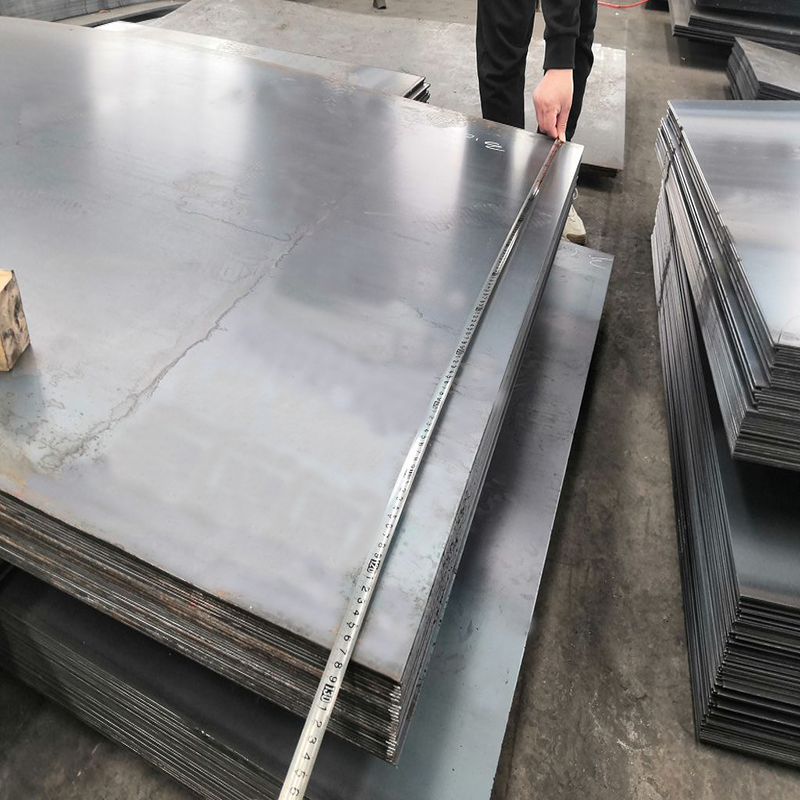

structural i beam

A structural I beam, also known as an H-beam or W-beam, represents a fundamental component in modern construction and engineering. This versatile structural element features a distinctive cross-sectional shape resembling the letter 'I', consisting of two horizontal flanges connected by a vertical web. The design maximizes strength while minimizing material usage, making it highly efficient for load-bearing applications. The beam's top and bottom flanges effectively resist bending moments, while the web handles shear forces. These beams are manufactured from high-grade steel through hot rolling processes, ensuring consistent quality and dimensional accuracy. I beams come in various standardized sizes and specifications, allowing engineers and architects to select the perfect match for their specific requirements. Their primary function involves supporting substantial loads in both commercial and industrial construction, particularly in multi-story buildings, bridges, and industrial facilities. The beam's geometry provides excellent strength-to-weight ratios, making it economical and practical for large-scale projects. Modern manufacturing techniques ensure precise tolerances and superior finish quality, contributing to easier installation and longer service life.