tin plate steel

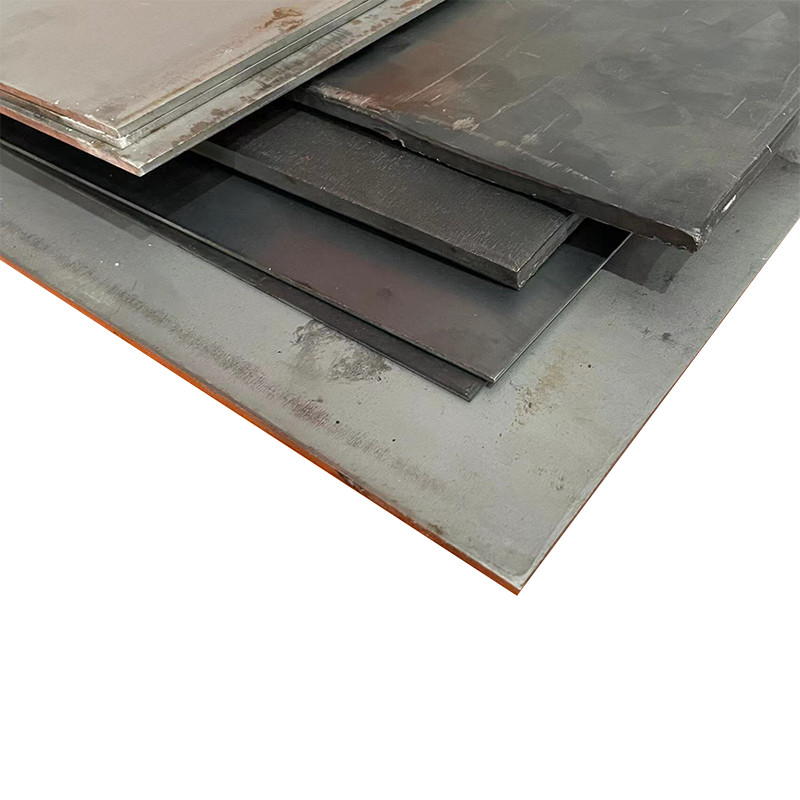

Tin plate steel represents a revolutionary material in modern manufacturing, combining the strength of steel with the corrosion resistance of tin. This innovative product consists of a thin sheet of steel coated with a layer of tin, typically applied through an electroplating process. The base steel provides structural integrity while the tin coating offers exceptional protection against oxidation and corrosion. The material's thickness typically ranges from 0.13mm to 0.5mm, making it versatile for various applications. The tin coating, usually applied in thicknesses of 2.8 to 11.2 g/m² per side, creates an impermeable barrier that prevents chemical reactions between the steel substrate and external elements. This combination results in a material that excels in food packaging, beverage containers, and industrial applications. The manufacturing process involves careful surface preparation, electrolytic tin coating, and heat treatment to ensure optimal adhesion and performance. The material undergoes rigorous quality control measures to maintain consistency in coating thickness, surface finish, and mechanical properties, ensuring reliability across diverse applications.