çərçivələnmiş spiral

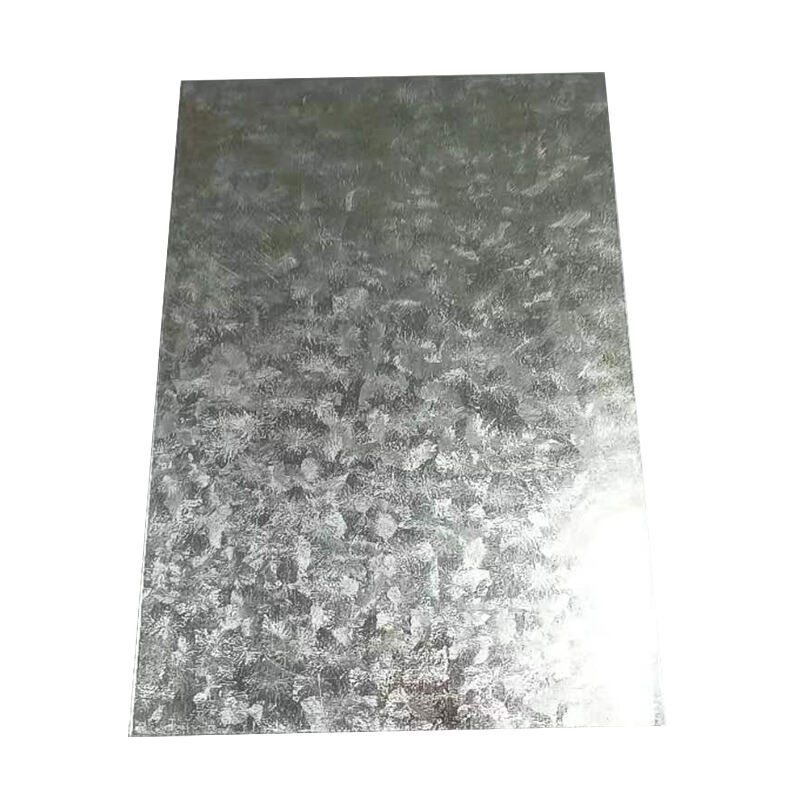

Stal rulonları emal edilmiş stal məhsulunun əsas formasını təmsil edir və onlar metalın kompakt silindr formalı rulonuna yığılmış kəsilməz uzunluğu ilə xarakterizə olunur. Bu çox yönlü məhsullar inkişaf etmiş val rollinq prosesləri vasitəsilə istehsal olunur, burada qalın stal lövhələr tədricən istənilən qalınlığa qədər nazikləşdirilir və sonra səmərəli saxlamaq və daşınmaq üçün diqqətlə rulonlanır. Rulonlar müxtəlif spesifikasiyalara, o cümlədən müxtəlif markalara, qalınlıqlara və enlərə malik olaraq istehsal oluna bilər ki, bu da onları müxtəlif sənaye tətbiqləri üçün uyğun edir. Müasir stal rulonları onların mexaniki xassələrini yaxşılaşdıran, məsələn, möhkəmlik, həssaslıq və korroziyaya davamlılığı artırmaq üçün inkişaf etmiş metallurgiya texnologiyalarını özündə birləşdirir. Onlar avtomobil, tikinti, mətbəx qurğuları və bağlama sənayesi kimi müxtəlif istehsal sahələrində əsas xammal kimi xidmət göstərir. Rulonlama prosesi yalnız yükləmə və saxlamanı asanlaşdırmır, həm də stalin səth keyfiyyətini və mexaniki xassələrini qorumağa kömək edir. Bu rulonlar müəyyən tətbiq tələblərinə cavab vermək üçün qalvanizasiya, rəngləmə və ya örtük kimi əlavə emal proseslərindən keçirilə bilər. İstehsal prosesi rulonun bütün uzunluğu üzrə sabit keyfiyyəti təmin etmək üçün temperaturun, gərginliyin və soyuma sürətinin dəqiq nəzarətini nəzərdə tutur.