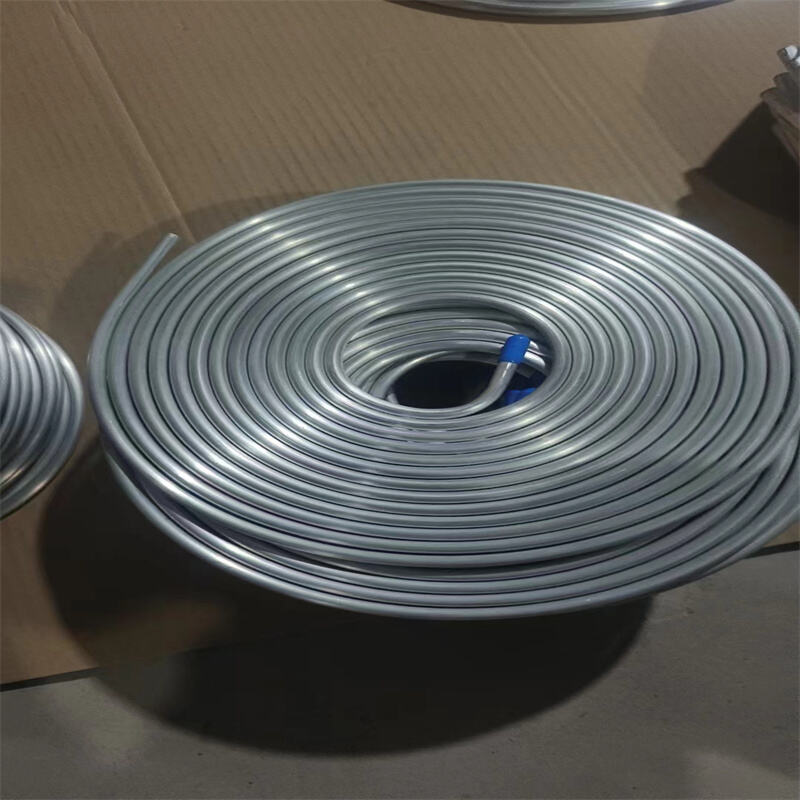

galvanizatutako zelai arrazional

Altzairu galbanizatuko angeluak eraikuntza eta industria arloetan erabiltzen diren egitura osagai garrantzitsuak dira. L formako metal produktu honek galbanizazio prozesu berezia jasaten du, geruzako babesa sortzeko zinkazko estalki bat aplikatuz korrosioa saihesteko eta bizitza luzatu ahal izateko. Fabrikazio prozesuan, altzairu angeluak 860°F (460°C) inguruko tenperaturan dauden zink urtutan murgiltzen dira, eta horrela lotura metalurgiko bat sortzen da, zink eta altzairuren arteko hainbat aleazio geruzak erakinez. Angelu hauek tamaina eta lodiera ezberdinetan daude, oro har 1mm-tik 6mm-ra bitartean, aplikazio ezberdinetarako erabilgarriak izateko. Gainazal galbanizatuak ingurumen faktuekiko babesa ahalbidetzen du, hezetasuna, kimikoak eta atmosferako baldintzak barne. Eraikuntzan, angelu hauek oinarrizko babes gisa erabiltzen dira egiturak, gurdiak eta sostenikuntza sistemak egiteko. Kanpoko aplikazioetan bereziki erabilgarriak dira, non altzairu arrunta errosio eta degradazioaren aurrean sentikorra izango litzatekeen. Galbanizazio prozesuak ez du iraupena handitzen baizik eta mantenu beharrak ere murrizten ditu, soluzio ekonomikoki eraginkorra izanik egitura aplikazio luze baterako.