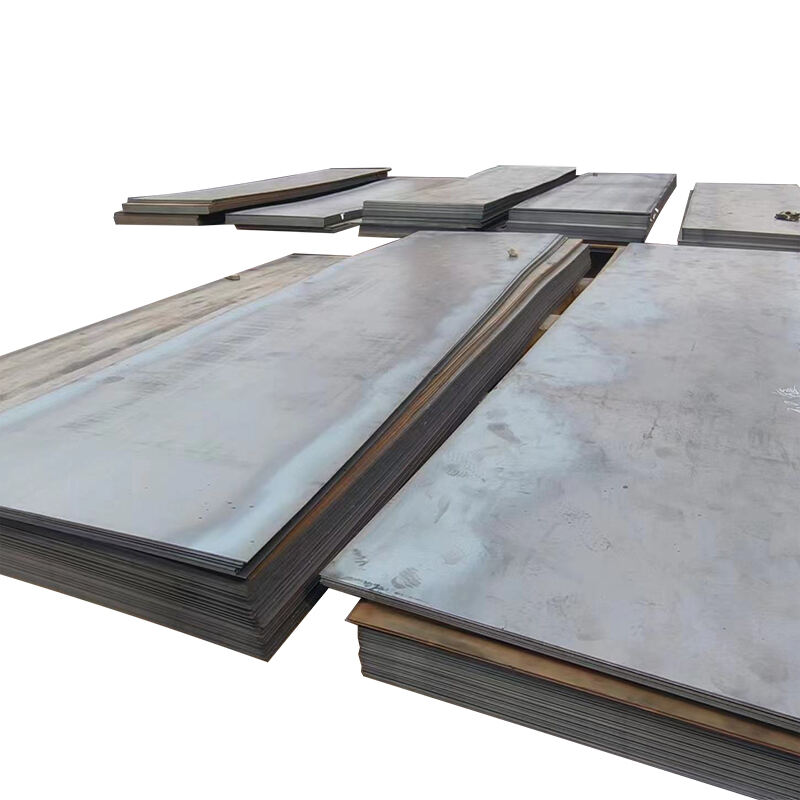

նիկելային թերթ

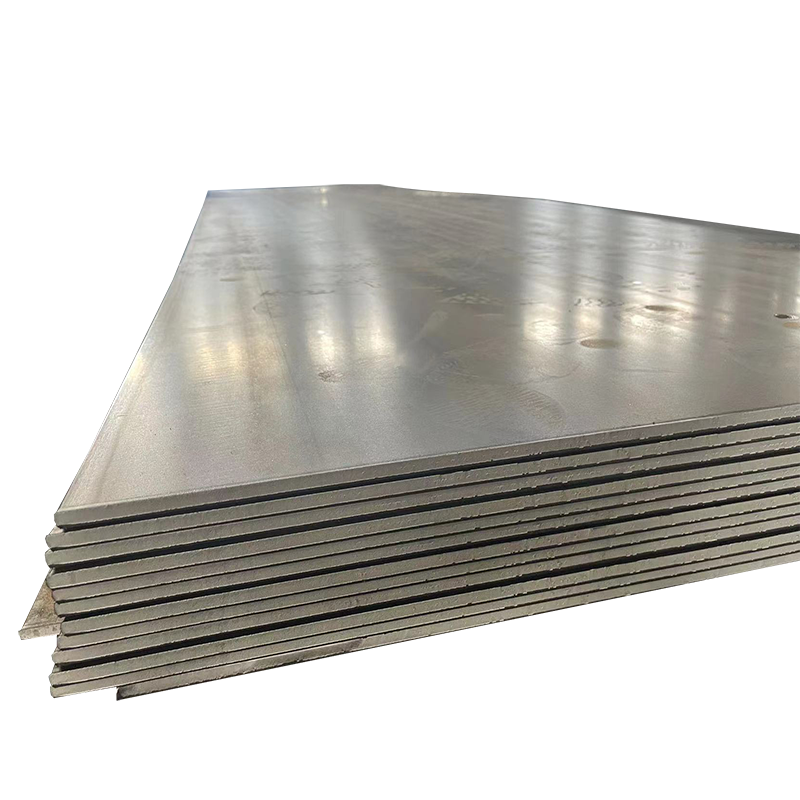

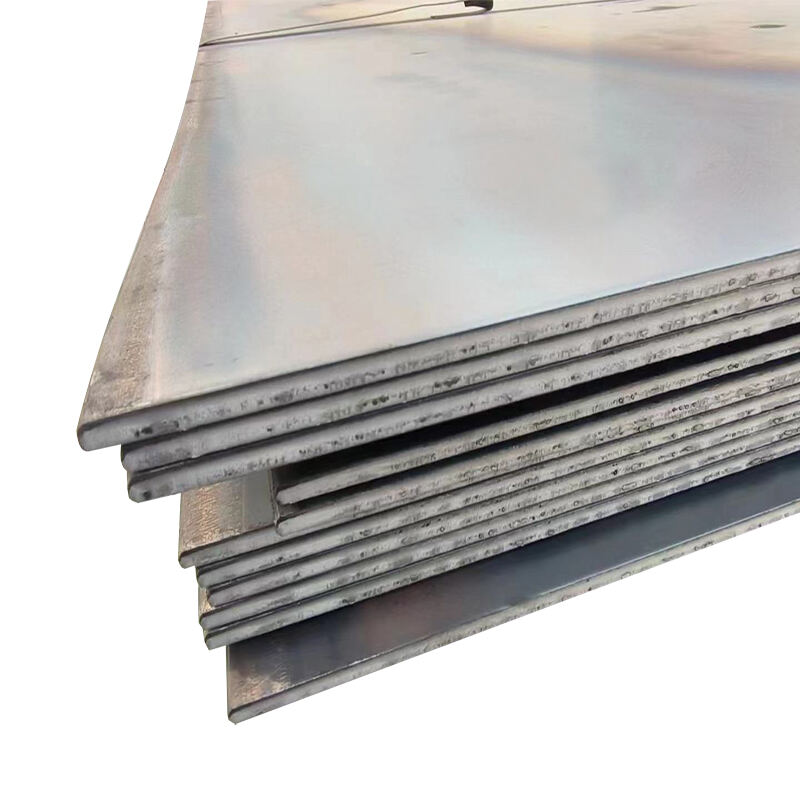

Նիկելե թիթեղը բազմակի նշանակության մետաղական նյութ է, որը համատեղում է բացառիկ տևականություն և կոռոզիայի ու ջերմության նկատմամբ հզոր դիմադրություն: Այս արդյունաբերական նմուշի ապրանքը բաղկացած է բարձր մաքրության նիկելից, որը ճշգրիտ արտադրական գործընթացների շնորհիվ ձևավորված է հարթ, համասեռ թիթեղների: Նյութն աչքի է ընկնում բարձր ամրությամբ ինչպես բարձր, այնպես էլ ցածր ջերմաստիճաններում, ինչը այն դարձնում է հարմար տարբեր արդյունաբերությունների համար նախատեսված բազմազան կիրառությունների համար: Նիկելե թիթեղները հասանելի են տարբեր հաստություններով, լայնություններով և մակնիշներով՝ բավարարելու հատուկ պահանջները: Նյութի հիանալի ձուլակերությունը թույլ է տալիս հեշտությամբ ձևավորել և ձուլել՝ պահպանելով կառուցվածքային ամբողջականությունը: Նյութի ներքին հատկություններից են գերազանց էլեկտրահաղորդման հնարավորությունը, մագնիսական թափանցելիությունը և օքսիդացման դիմադրությունը, ինչը այն անհրաժեշտ է դարձնում էլեկտրոնային, տիեզերական և քիմիական մշակման արդյունաբերություններում: Այս թիթեղները նաև ցուցադրում են հիանալի հալման հնարավորություն և կարող են հեշտությամբ միացվել ստանդարտ լցրակայման տեխնիկաների միջոցով: Մակերեսի վերջավորությունը կարող է տատանվել մատն մակերեսից մինչև հայելի փայլ, կախված կիրառման պահանջներից: Բացի այդ, նիկելե թիթեղներն ունեն հիանալի դիմադրություն ալկալային միջավայրերի նկատմամբ և պահպանում են իրենց մեխանիկական հատկությունները նույնիսկ ամենախիստ պայմաններում: