When it comes to selecting materials for outdoor projects and applications, carbon steel emerges as a compelling option that demands careful consideration. This versatile material has been a cornerstone in construction, manufacturing, and various industrial applications for generations. However, its suitability for outdoor use requires a thorough understanding of its properties, limitations, and the measures needed to optimize its performance in external environments.

Carbon steel's behavior in outdoor settings is influenced by multiple factors, including environmental conditions, protective measures, and specific application requirements. While some might initially hesitate to use carbon steel outdoors due to corrosion concerns, proper knowledge and implementation of protective strategies can make it an excellent choice for many exterior applications.

Carbon steel's remarkable strength-to-weight ratio makes it an attractive option for outdoor structural applications. The material exhibits excellent tensile strength and load-bearing capabilities, which are crucial for construction projects and outdoor infrastructure. In properly protected conditions, carbon steel can maintain its structural integrity for decades, supporting heavy loads and withstanding various environmental stresses.

The mechanical properties of carbon steel remain stable across a wide range of temperatures, making it suitable for diverse climatic conditions. This consistency in performance contributes to its reliability in outdoor applications, from bridges to storage tanks.

While carbon steel outdoor applications require appropriate protection, the material's inherent durability contributes to its longevity. When properly treated and maintained, carbon steel can withstand harsh weather conditions, including extreme temperatures, heavy rainfall, and snow. The key lies in implementing effective protective measures that shield the steel from direct exposure to elements that could accelerate corrosion.

The material's ability to handle thermal cycling - the repeated heating and cooling that occurs in outdoor environments - makes it particularly valuable for exterior installations. This characteristic helps prevent structural fatigue and maintains the integrity of outdoor installations over time.

The success of carbon steel outdoor applications largely depends on the implementation of appropriate protective measures. Surface treatments play a crucial role in preventing corrosion and extending the material's service life. Popular coating options include hot-dip galvanization, powder coating, and specialized paint systems designed for industrial applications.

Modern protective coatings can provide multiple layers of defense against environmental factors. These treatments not only prevent corrosion but also enhance the aesthetic appeal of carbon steel structures, making them suitable for architectural applications where appearance matters.

Regular maintenance is essential for ensuring the longevity of carbon steel in outdoor settings. This includes periodic inspections for signs of coating damage or corrosion, prompt repairs of any compromised protective layers, and cleaning to remove accumulated debris or contaminants that could compromise the material's integrity.

A well-planned maintenance schedule can significantly extend the service life of carbon steel installations and prevent costly repairs or replacements. This proactive approach helps maintain both the functional and aesthetic aspects of outdoor steel applications.

Carbon steel outdoor applications are prevalent in infrastructure development, where the material's strength and durability are paramount. From bridge construction to highway guardrails, carbon steel continues to prove its worth in large-scale outdoor projects. The material's versatility allows engineers to create robust structures that can withstand both environmental pressures and heavy use.

The success of carbon steel in infrastructure projects often stems from careful planning and implementation of protective measures during the design phase. This forward-thinking approach ensures optimal performance throughout the structure's intended lifespan.

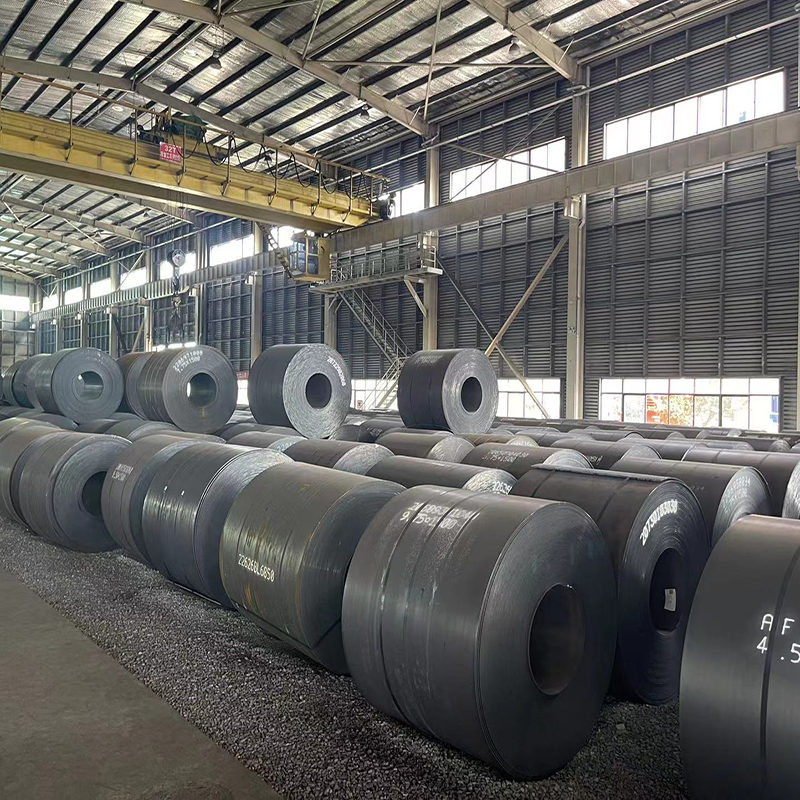

In industrial settings, carbon steel finds numerous outdoor applications, from storage tanks to processing equipment. The material's ability to handle various chemical compounds, when properly protected, makes it suitable for diverse industrial uses. Commercial applications often include outdoor furniture, architectural elements, and security installations.

The cost-effectiveness of carbon steel, combined with its strength and durability, makes it an attractive option for businesses looking to balance performance with budget considerations. Successful implementations often showcase the material's versatility and reliability in challenging outdoor environments.

When evaluating carbon steel outdoor applications, environmental impact becomes an important consideration. The material's high recyclability rate makes it an environmentally responsible choice, as steel can be repeatedly recycled without losing its essential properties. This characteristic contributes to the circular economy and reduces the overall environmental impact of construction and manufacturing projects.

The production of carbon steel does have an environmental footprint, but ongoing technological improvements in manufacturing processes are helping to reduce emissions and energy consumption. The material's longevity in outdoor applications, when properly protected, also contributes to its sustainability profile.

The environmental performance of carbon steel in outdoor settings extends beyond its initial installation. With proper maintenance and protection, carbon steel structures can serve their intended purpose for many decades, reducing the need for replacement and the associated environmental impacts of new construction or manufacturing.

Additionally, innovations in protective coatings and treatments continue to improve the material's resistance to environmental factors, further extending its service life and enhancing its sustainability credentials.

With proper protection and maintenance, carbon steel can last several decades in outdoor applications. The actual lifespan depends on factors such as environmental conditions, quality of protective coatings, and maintenance practices. Many carbon steel structures have remained in service for 50 years or more when properly maintained.

The most effective protective treatments include hot-dip galvanization, high-performance paint systems, and powder coating. The choice of protection depends on the specific application, environmental conditions, and aesthetic requirements. Multiple layers of protection often provide the best results for outdoor applications.

While stainless steel offers inherent corrosion resistance, properly protected carbon steel can be equally suitable for many outdoor applications. Carbon steel typically offers higher strength at a lower cost, making it an economical choice when appropriate protective measures are implemented. The choice between the two materials often depends on specific project requirements, budget constraints, and environmental conditions.

Hot News

Hot News2025-01-03

2024-10-23

2024-11-15