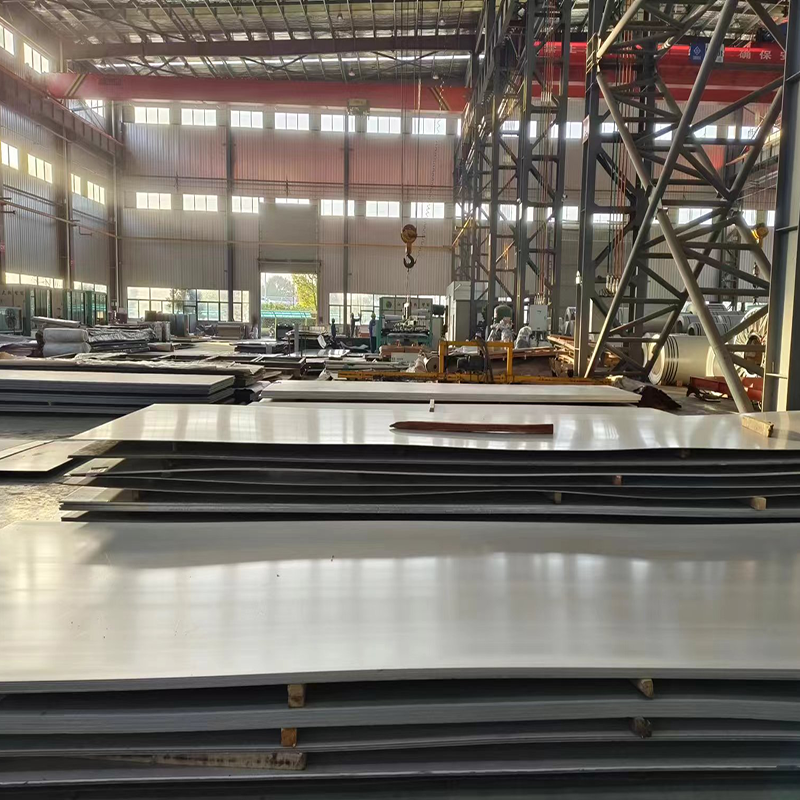

304 þéttur af rjúpastaði

304 rostfreðar stálsplötu er talin algengasta og ýmist notaða tegund rostfrjáss stáls á markaðnum. Þessi austenít-krom-níkel legering inniheldur um það bil 18% krom og 8% níkel, sem býr til efni sem erður vel í móti rostmyndun og er varanlegt. Plötulaga gefur frábæra myndunarefni og sveiflugetu, sem gerir hana sérlega hentuga fyrir fjölda framleiðsluaðferða. Þar sem hún er óflúin og getur viðhaldið upp á byggingarheild á víðu hitasviði er hún sérstaklega gagnleg í ýmsum iðnaðarforritum. Efnið hefur frábæra andvirkni gegn oxun, sérstaklega við hita upp í 870°C, og varðveitir frábæra vélaeiginleika jafnvel í kryðju aðstæðum. 304 tegundin hefur einnig áverka betri hreiniliskenningar, með sléttu yfirborði sem kemur í veg fyrir vöxt baktería og auðveldar hreinsun, sem gerir hana að yfirstandandi vali í matvælaframleiðslu og framleiðslu lækningatækja. Því einnig fjölbreytileiki plötunnar í útliti, með ýmsum yfirborðsmeðferðum frá spegla yfirborði til dulurts yfirborði, sem hentar bæði virkum og tæknilegum kröfum.