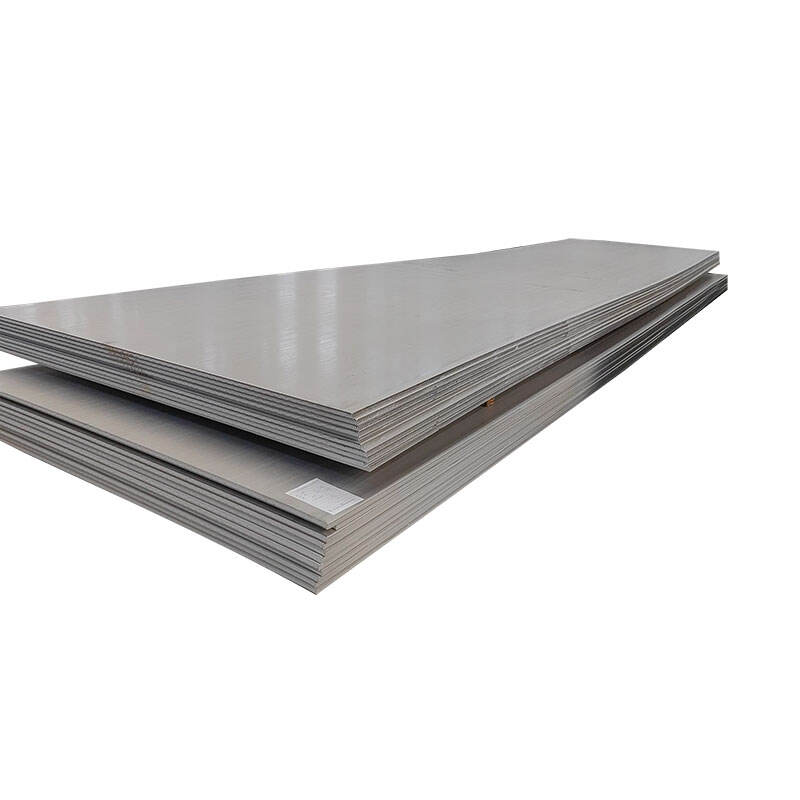

kalt hrunnar rostfrjáls stálhvel

Köldvalsaður rostfrelsistálsspóla er hásköðuligur málmarafnur framleiddur með flókið valsnunaraferð, þar sem rostfrelsistáli er vinnur í stofuhit til að ná í betri yfirborðsferð og nákvæma stærðarstýringu. Þessi framleiðsluaðferð minnkar verulega þykkt hitavalda stálsins en á sama tíma bætir henni lánnaeiginleikum og yfirborðseiginleikum. Ferlið felur í sér að láta efnið fara í gegnum fjölda valsnara undir háum þrýstingi, sem leidir til þess að framleiðslan hefur framúrskarandi sléttu, betri styrkleika og frábæra mæligildanákvæmni. Þessar spólar eru fáanlegar í ýmsum tegundum, þar á meðal austenít, ferrít og martensít, hver og ein sérstakir eiginleikar sem henta sér til ýmissa notkunar. Eiginleg rostverndun efnisins, ásamt bættum lánnaeiginleikum, gerir það að órslitni vali fyrir fjölda iðnaðar, frá bíl- og byggingaiðnaði til matvælaverðsköpunar og framleiðslu á lækningatækjum. Kaldvalsnunaraferðin gefur einnig sléttu, glæsilega yfirborðsferð sem getur verið frá dulitri til speglaðs, eftir því hvaða kröfur eru á endanlega notkun.