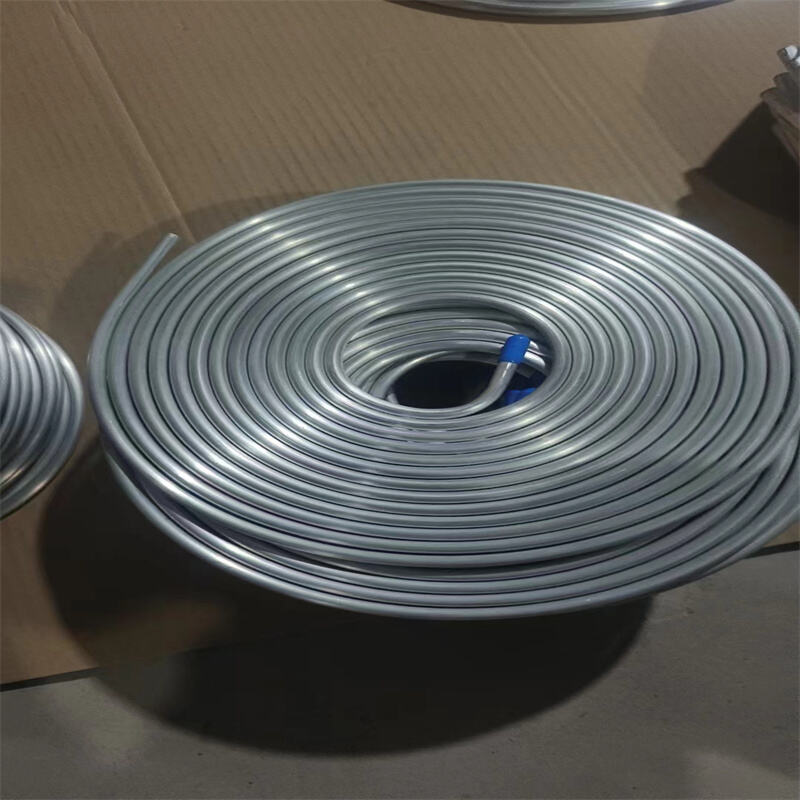

angolo in acciaio galvanizzato

L'acciaio zincato a caldo rappresenta un componente strutturale fondamentale, ampiamente utilizzato nei settori delle costruzioni e della produzione industriale. Questo prodotto metallico a forma di L subisce un processo speciale di zincatura nel quale viene applicato un rivestimento protettivo in zinco per prevenire la corrosione e prolungarne la durata. Il processo produttivo prevede la zincatura a caldo, durante la quale gli angolari in acciaio vengono immersi in zinco fuso a temperature di circa 860°F (460°C), creando un legame metallurgico che forma diversi strati di lega zinco-ferro. Gli angolari sono disponibili in varie dimensioni e spessori, generalmente compresi tra 1 mm e 6 mm, il che li rende versatili per differenti applicazioni. Il rivestimento zincato offre un'elevata protezione contro i fattori ambientali, tra cui l'umidità, i prodotti chimici e le condizioni atmosferiche. Nel settore edile, questi angolari costituiscono supporti essenziali per strutture portanti, staffe e sistemi di controventamento. Sono particolarmente utili in applicazioni esterne dove l'acciaio normale sarebbe soggetto a ruggine e degrado. Il processo di zincatura non solo aumenta la durabilità, ma riduce anche le esigenze di manutenzione, rappresentando una soluzione economica per applicazioni strutturali a lungo termine.