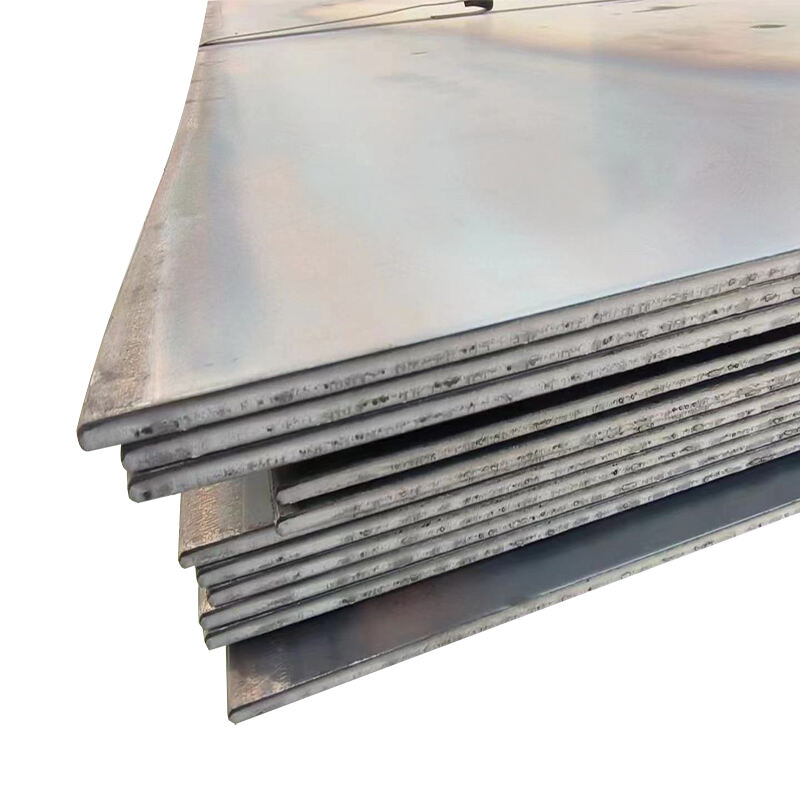

sbarra d'acciaio dolce

La barra di acciaio dolce rappresenta un elemento fondamentale nei settori moderni della costruzione e della produzione industriale. Questo materiale versatile, composto principalmente da ferro con un basso contenuto di carbonio generalmente compreso tra lo 0,05% e lo 0,25%, offre un eccellente equilibrio tra resistenza, lavorabilità ed economicità. Queste barre vengono prodotte attraverso un processo controllato di laminazione a caldo che garantisce una qualità costante e una precisa tolleranza dimensionale. Disponibili in diverse forme, tra cui profili rotondi, quadrati e rettangolari, le barre di acciaio dolce costituiscono componenti essenziali per applicazioni strutturali, costruzione di macchinari e lavorazioni generiche di carpenteria. Le proprietà intrinseche del materiale lo rendono particolarmente adatto alle operazioni di saldatura, taglio e formatura, mentre la sua composizione uniforme assicura prestazioni prevedibili in diverse applicazioni. Il processo produttivo include un preciso controllo della temperatura e dei tassi di raffreddamento, generando un prodotto che presenta proprietà meccaniche affidabili, come buona resistenza alla trazione, duttilità ed elevata resistenza all'impatto. Nel settore edile, le barre di acciaio dolce vengono utilizzate estensivamente come armatura nelle strutture in calcestruzzo, nelle strutture portanti e nei sistemi di supporto. La loro ampia applicazione industriale spazia tra componenti automobilistici, produzione di attrezzature e sviluppo di infrastrutture, rendendole un materiale indispensabile nelle applicazioni ingegneristiche moderne.