304ステンレス鋼管

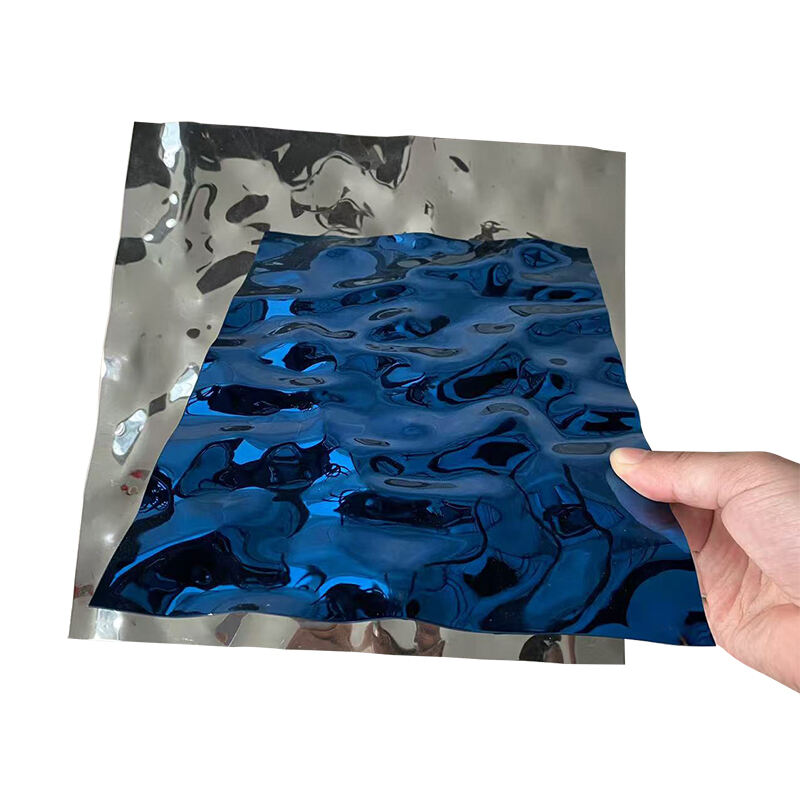

304ステンレス鋼管は、現代の冶金工学の到達点であり、優れた耐久性と多用途な機能性を兼ね備えています。このオーステナイト系鋼種は、約18%のクロムと8%のニッケルからなる正確な組成を有しており、腐食抵抗性に優れ、多様な環境下でも構造的な完全性を維持します。この鋼管は、固溶化熱処理や高精度成形などの厳格な製造工程を経ており、一貫した品質と寸法精度を確保しています。これらの管材は、食品加工機器や化学物質輸送システムから建築用インスタレーションや医療機器に至るまで、さまざまな業界で広く使用されています。非磁性特性と優れた溶接性を持つため、特に複雑な製造プロジェクトに最適です。また、極低温から1600°Fまでの温度に機械的特性を維持する能力があるため、熱交換システムや圧力用途において非常に価値があります。さらに、304ステンレス鋼管は滑らかな表面仕上げが得られるため、最適な流体特性を実現し、清掃作業を容易にします。これにより、衛生用途に最適な素材となっています。