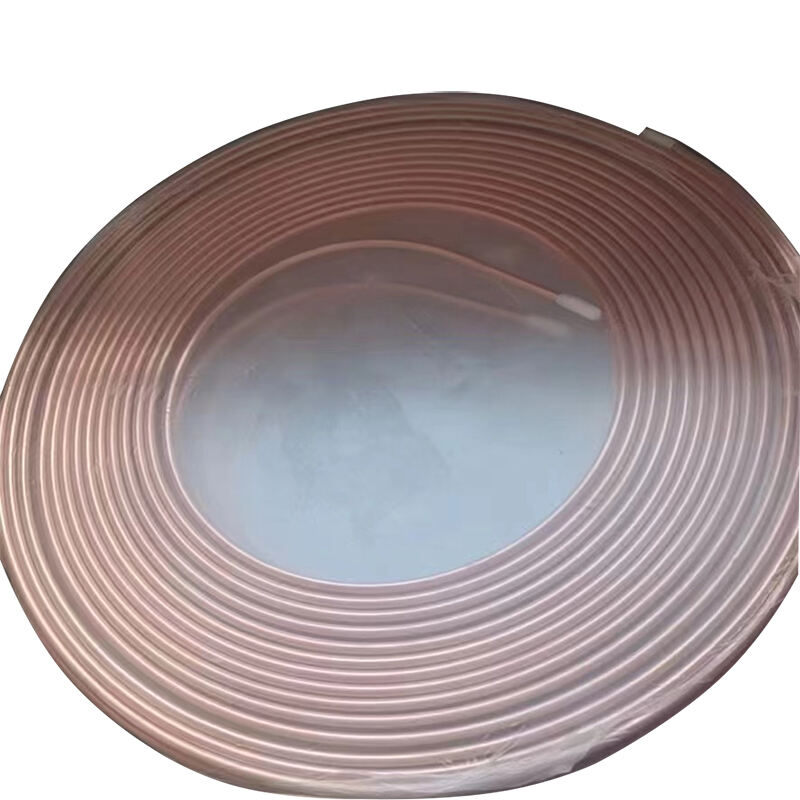

रंगीन ओळखलेली फूल कोइल

रंगीत पोलादी कॉइल ही धातू प्रक्रिया मधील एक उत्कृष्ट प्रगती आहे, जी टिकाऊपणा आणि सौंदर्य यांचे संयोजन करते. हा बहुमुखी इमारत सामग्रीतील पोलादी आधारावर उष्ण विलीन झांक लेपन केले जाते, त्यानंतर पृष्ठभागाची काही उपचार प्रक्रिया आणि उच्च कार्यक्षमता वाल्या रंगाच्या प्रणालीचे अनुप्रयोग केले जातात. उत्पादन प्रक्रियेत एकसमान आवरण आणि उत्कृष्ट चिकटण्याची खात्री करण्यासाठी अचूक तापमान नियंत्रण आणि आधुनिक लेपन तंत्रज्ञानाचा समावेश आहे. ह्या कॉइलमध्ये सामान्यतः अनेक स्तर असतात, ज्यामध्ये दगडी प्रतिकारासाठी झिंक लेप, रंगाच्या चिकटण्यासाठी प्राइमर आणि रंग आणि संरक्षण दोन्ही पुरवणारा शीर्ष थर असतो. रंग, परिमाणे आणि जाडीच्या विस्तृत श्रेणीमध्ये उपलब्ध असलेल्या रंगीत पोलादी कॉइलमध्ये अतुलनीय हवामान प्रतिकार, यूव्ही संरक्षण आणि उष्णता स्थिरता आहे. उत्पादनाची बहुमुखीता त्याला छप्पर, भिंतीचे आवरण ते आतील सजावटीच्या घटकांपर्यंत विविध अनुप्रयोगांसाठी आदर्श बनवते. वापरलेल्या लेपन तंत्रज्ञानामुळे दीर्घकाळ रंग स्थिरता राहते आणि कठोर पर्यावरणीय परिस्थितीमध्ये सुद्धा चूर्ण होणे, उतरणे आणि मलीन होणे रोखते. आधुनिक उत्पादन पद्धतीमध्ये पर्यावरणाचा विचार केला जातो, अनेकदा पर्यावरणपूरक लेपन सामग्री आणि ऊर्जा क्षमतेने काम करणारी प्रक्रिया वापरली जाते. उत्पादनाचे हलके स्वरूप, त्याच्या शक्ती आणि टिकाऊपणासह जोडल्याने ते राहणीमय आणि व्यावसायिक बांधकाम प्रकल्पांसाठी आर्थिकदृष्ट्या व्यवहार्य पर्याय बनवते.