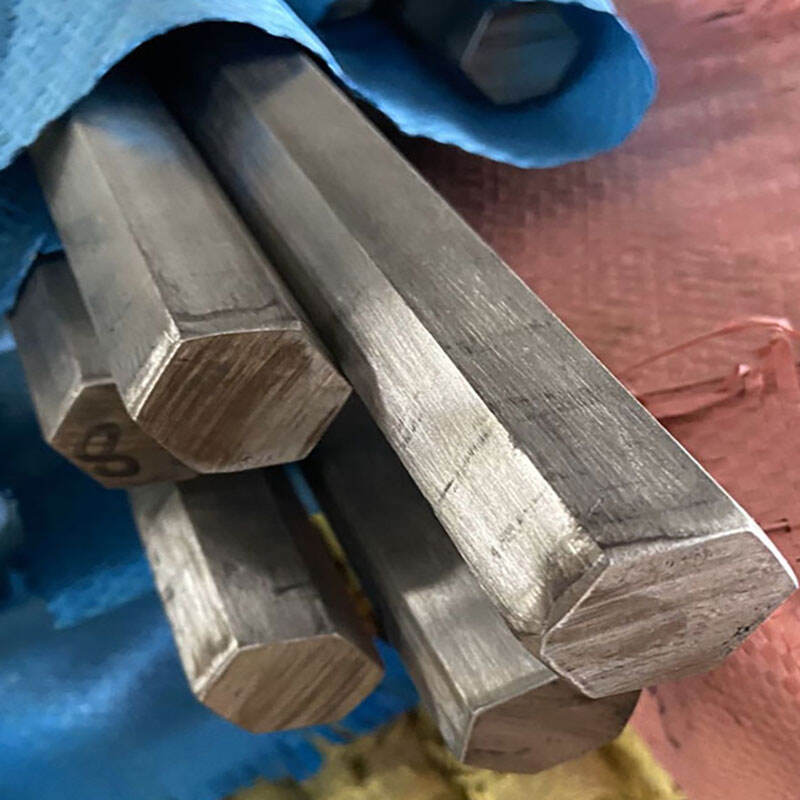

paip keluli 904l

tiub keluli tahan karat 904L merupakan penyelesaian keluli austenitik berprestasi tinggi yang direka bentuk untuk aplikasi industri mencabar. Bahan gred premium ini menawarkan rintangan yang luar biasa terhadap kakisan, terutamanya dalam persekitaran agresif yang mengandungi klorida dan asid sulfurik. Komposisi kimia unik tiub ini, yang mempunyai kandungan nikel dan molibdenum yang lebih tinggi berbanding gred keluli tahan karat biasa, membolehkannya mengekalkan keutuhan struktur dalam keadaan melampau. Dikenali dengan sifat mekanikal yang cemerlang pada suhu tinggi dan cryogenic, tiub keluli tahan karat 904L menunjukkan kebolehelasan dan kebolehbentukan yang unggul. Tiub ini digunakan secara meluas dalam kelengkapan pemprosesan kimia, penukar haba, instalasi minyak dan gas lepas pantai, serta aplikasi marin di mana gred keluli tahan karat biasa mungkin gagal. Kandungan karbon yang rendah dalam bahan ini menghalang pengkarbonan semasa kerja pengimpalan, memastikan prestasi yang konsisten sepanjang hayat penggunaannya. Tambahan pula, rintangan tingginya terhadap kakisan pit dan kakisan celah menjadikannya sangat sesuai untuk aplikasi air laut dan proses yang melibatkan halida. Tiub ini dikeluarkan di bawah langkah kawalan kualiti yang ketat untuk mengekalkan ketepatan dimensi dan kemasan permukaan, memastikan prestasi yang boleh dipercayai dalam aplikasi kritikal.