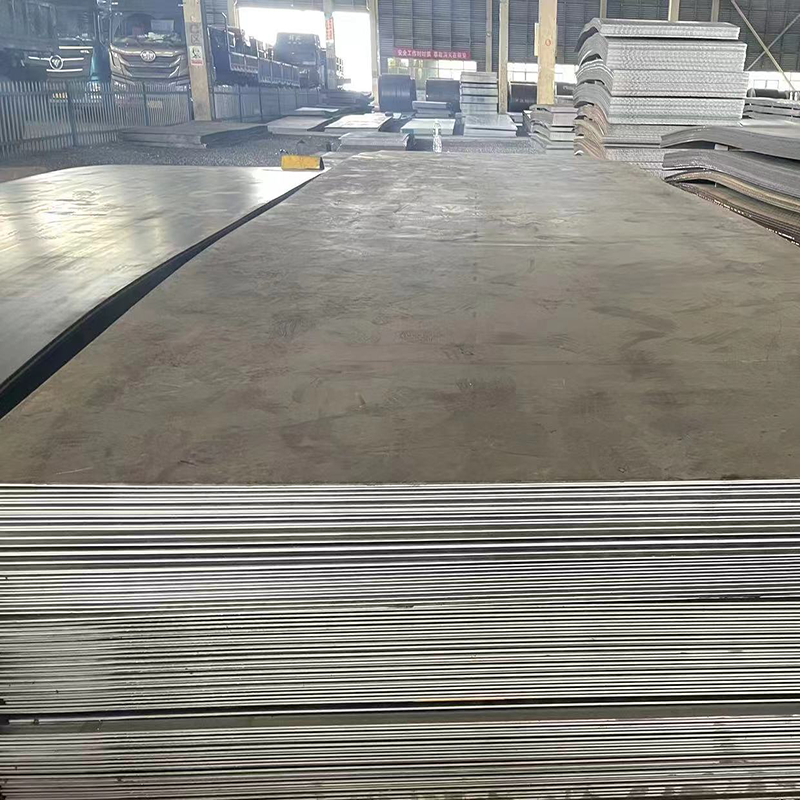

palang keluli datar

Bar keluli satah merupakan komponen asas dalam pembinaan dan pembuatan moden, yang dicirikan oleh keratan rentas segi empat tepat yang seragam dan sifat berdimensi konsisten. Bahan yang pelbagai guna ini dihasilkan melalui proses penggulingan panas atau penarikan sejuk, menghasilkan spesifikasi yang tepat untuk lebar dan ketebalan. Bar keluli satah direka bentuk untuk memberikan prestasi yang optimum dalam pelbagai aplikasi memikul beban, menawarkan nisbah kekuatan-kepada-berat yang luar biasa serta ketahanan. Proses pengeluaran memastikan toleransi berdimensi ketat, permukaan yang licin, dan sifat mekanikal yang konsisten sepanjang panjang bar tersebut. Bar ini tersedia dalam pelbagai gred keluli, termasuk keluli karbon, keluli aloi, dan keluli tahan karat, di mana setiap satunya menawarkan kelebihan tertentu untuk pelbagai aplikasi. Mereka bertindak sebagai elemen penting dalam kerangka struktur, komponen mesin, dan pemasangan arkitek. Kaedah pengeluaran yang piawa memastikan kawalan kualiti yang boleh dipercayai, menjadikan bar keluli satah sebagai pilihan ideal untuk aplikasi yang memerlukan spesifikasi tepat dan prestasi konsisten. Keluwesan mereka merangkumi kegunaan kedua-dua industri dan komersial, dari pembuatan jentera berat hingga elemen arkitek hiasan.