ဂယ်လ်ဝါက် ကုတ်များနှင့် စာရင်းများ: မီတာလ်အသုံးပြုမှုတွင် အရည်ပင်မှုကို တိုးတက်ခြင်း

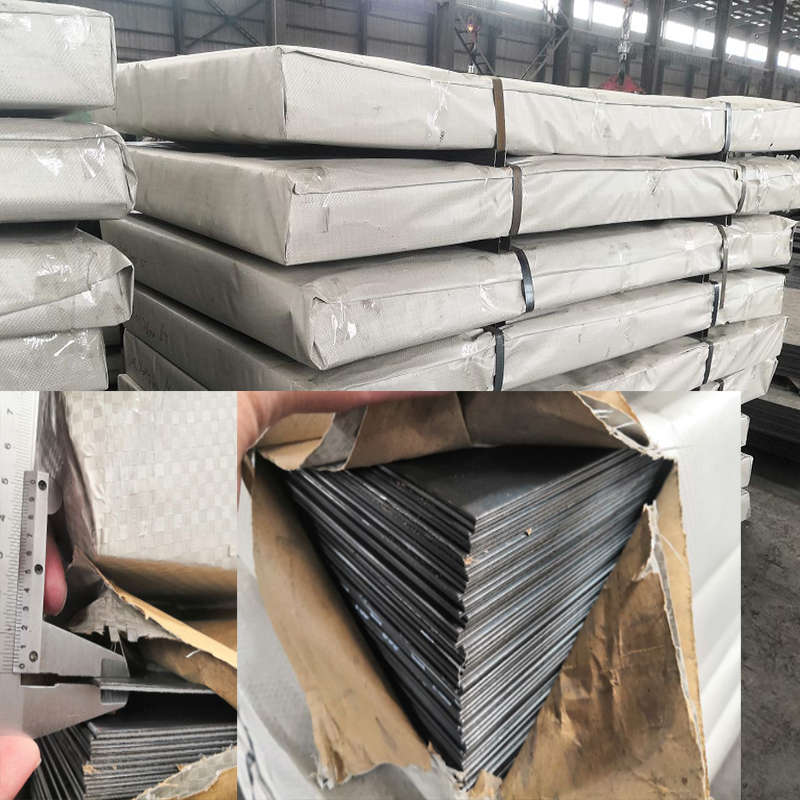

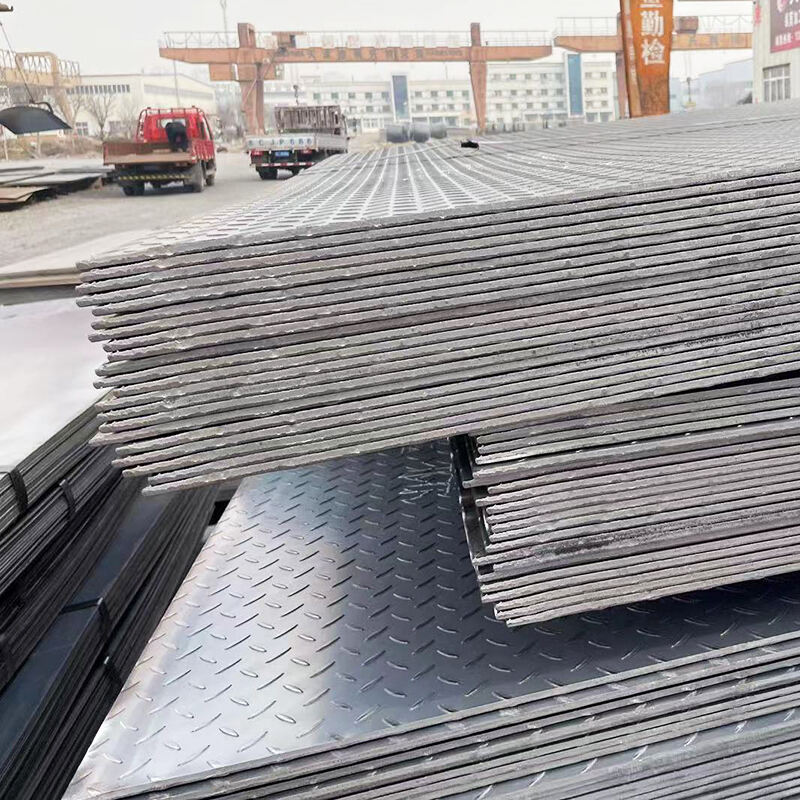

ဂလင်ဖ်ကိုယ်များနှင့် စာရင်းများ၏ အမြဲတမ်းသော အသုံးဝင်မှုများနှင့် အသုံးပြုမှုများကို တွေ့ရှိပါ။ ဇင်းဖြင့် အခြားမှန်သော အသေးစိတ်ဖြင့် ထပ်ဆောင်းထားသည့် အားပိုင်းများ၏ အားကစားမှု၊ အရှည်ကြာမှုနှင့် ကျွန်သုံးသပ်မှုကို သိရှိပါ။ ဘုံတော်တော်ကြီးများ၊ အုတ်မြောင်းများနှင့် သမုဒ္ဒရာလုပ်ငန်းများတွင် အားပိုင်းများကို အသုံးပြုသည့် အဓိကအချက်များကို သိရှိပါ။

ပိုမိုကြည့်ရှုပါ။