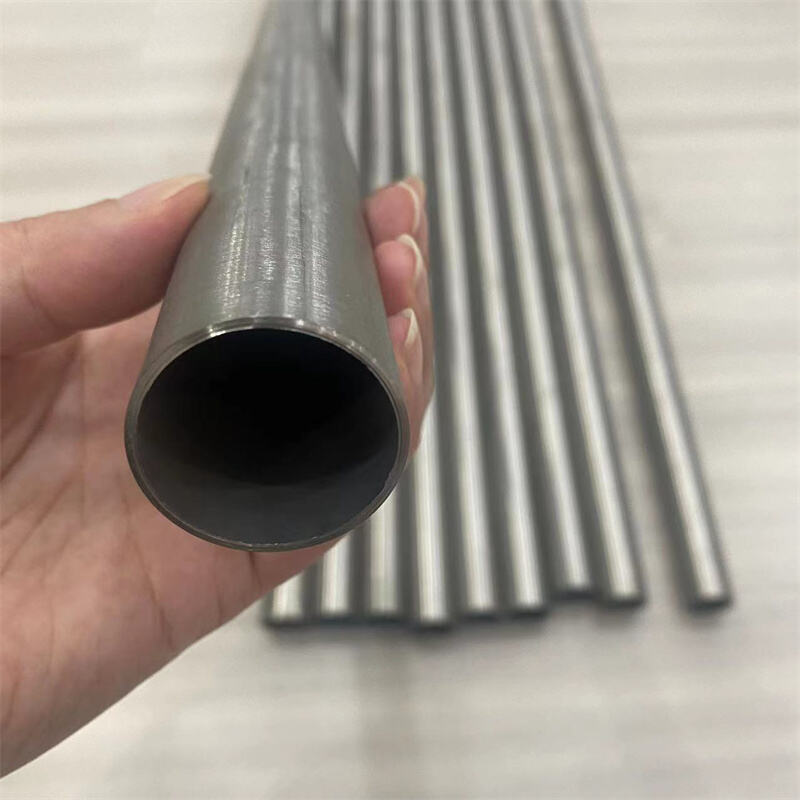

tubo de titânio de parede fina

O tubo de titânio de parede fina representa uma conquista notável em engenharia, combinando resistência excepcional com uso mínimo de material. Esses tubos especializados possuem espessuras de parede geralmente variando entre 0,008 e 0,060 polegadas, mantendo ao mesmo tempo uma integridade estrutural superior. Fabricados por meio de processos avançados de engenharia de precisão, esses tubos oferecem um equilíbrio ideal entre redução de peso e desempenho. As funções principais incluem o transporte de fluidos em aplicações aeroespaciais, sistemas de processamento químico e fabricação de dispositivos médicos. As características tecnológicas incorporam processos metalúrgicos de ponta que garantem espessura uniforme da parede, excelente resistência à corrosão e uma proporção superior entre resistência e peso. Esses tubos são particularmente valiosos em aplicações que exigem alto desempenho sob condições extremas, como ambientes de alta temperatura ou exposição a produtos químicos corrosivos. O processo de fabricação envolve técnicas sofisticadas, como extrusão sem costura ou soldagem, seguidas por rigorosas medidas de controle de qualidade para garantir precisão dimensional e consistência do material. Sua biocompatibilidade os torna ideais para aplicações médicas, enquanto suas excelentes propriedades de transferência de calor os adequam para sistemas de trocadores de calor. A combinação de construção leve e durabilidade excepcional torna os tubos de titânio de parede fina um componente essencial nas aplicações industriais e tecnológicas modernas.