čelikaša

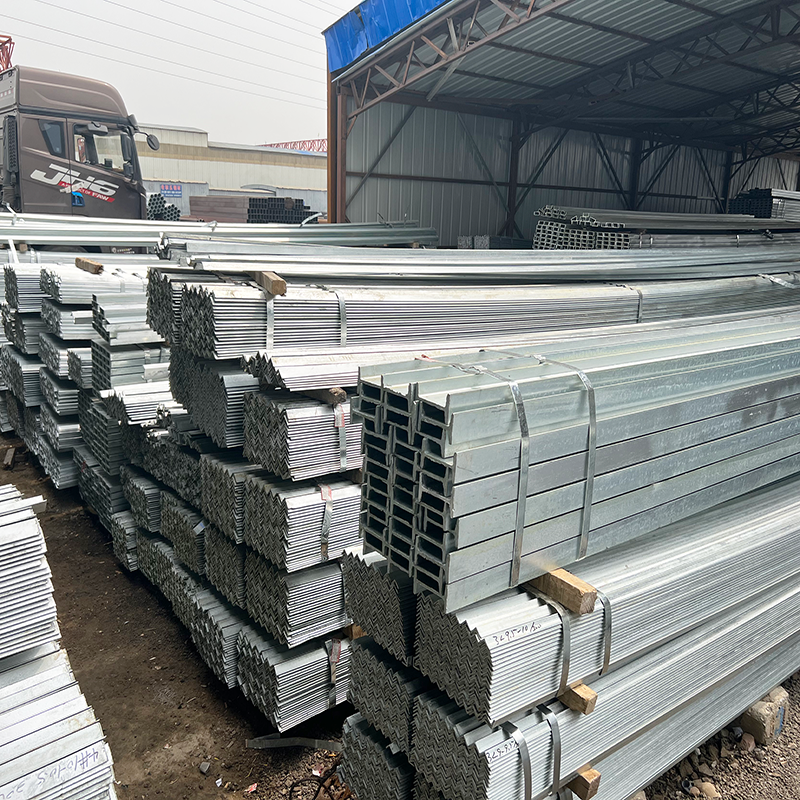

Равни челични профил представља основни и свестрано употребљив саставни део у модерној градитељској и индустријској производњи. Овај основни материјал има правоугаони пресек са једнаком дебљином и ширином, који се производи путем процеса врућег ваљања или хладног обликовања ради поштовања прецизних спецификација. Производни процес обезбеђује сталну тачност димензија и структурну интегритет дуж целокупне дужине. Равни челични профили доступни су у различитим класама, као што су благи челик, угљенични челик и нерђајући челик, при чему свака класа има својства прилагођена различитим применама. Ови профили истичу се у применама са великим оптерећењем, нудећи изузетан однос чврстоће и тежине и поуздан рад у разним климатским условима. Свестрана примена равних челичних профила обухвата бројне индустрије, од структурне подршке у градитељству до саставних делова машине и опреме. Они представљају критичне елементе у изради носача, упора, оквирних конструкција и арматурних примена. Стандардизовани методи производње обезбеђују једноликост у механичким карактеристикама, као што су чврстоћа на затегање, гранична чврстоћа и стабилност димензија. Современе производне технике омогућавају прилагођавање спецификација, укључујући разне дужине, ширине и дебљине, чиме се равни челични профили прилагођавају разноликим захтевима пројеката. Трајност материјала и отпорност на хабање чине га посебно погодним за примене које захтевају дуготрајну структурну интегритет и минималну одржавање.