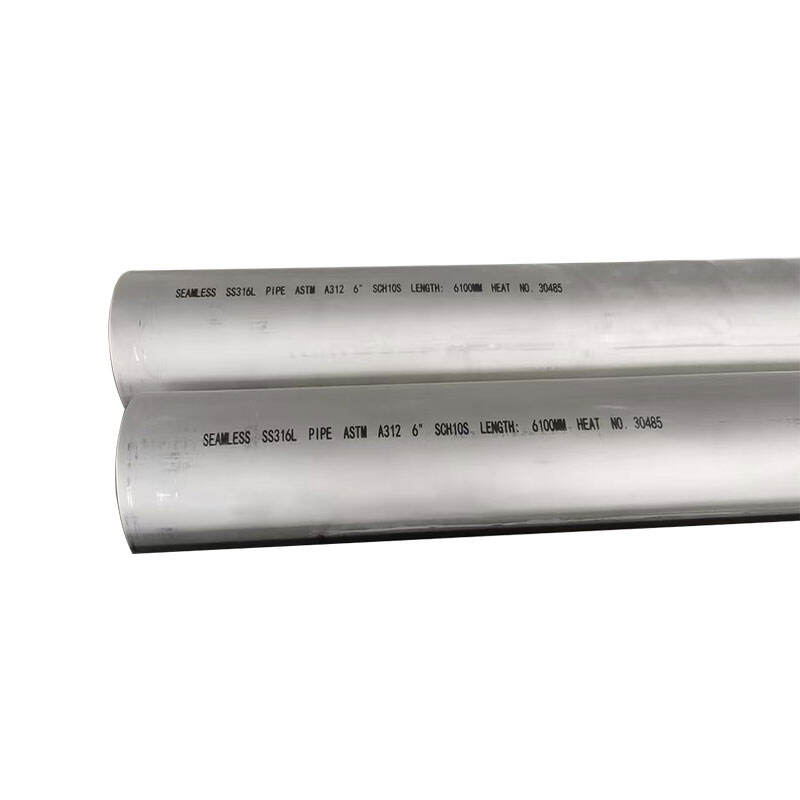

Sanoat sohasida turli sohalarda qo'llanilayotgan narsalar tufayli sanoatdagi vaziyat tubdan o'zgardi zanglamaydigan po'latdan chiziqlar ushbu mustahkam komponentlar bir nechta sanoat jarayonlarining asosiy tayanchiga aylangan bo'lib, yuqori samaradorlik va ishonchlilikni ta'minlaydi. Kimyoviy ishlashdan tortib, oziq-ovqat ishlab chiqarishgacha bo'lgan sohalarda, shaffof po'lat quvurlar o'ttiz yillar davomida muvaffaqiyatli qo'llanilganligi bilan o'z qiymatini isbotlagan.

Birgalikda naychalarga bo'lgan o'sayotgan talab ularning ajoyib ko'p maqsadliligi va yuqori sifatli xususiyatlarini aks ettiradi. Zamonaviy sanoat tashkilotlari strukturaviy butunlikni va operatsion samaradorlikni saqlab turuvchi ekstremal sharoitlarga chidasa biladigan quvurlar yechimlariga ehtiyoj sezadi. Birgalikda naychalar ushbu qattiq talablarga javob beradi hamda sanoat sohasida foydalanish uchun arzon, uzoq muddatli yechim taklif etadi.

Birgalikda naychalarning eng muhim afzalliklaridan biri — ularning ajoyib korroziyaga chidamliligidir. Birgalikda po'latdagi xrom tarkibi rustlanish va degradatsiyani oldini oladigan himoya qiluvchi oksid qavatini hosil qiladi, hatto qattiq atrof-muhit sharoitlarida ham. Bu o'zini tiklovchi himoya parda uzun muddat davomida birgalikda naychalarning tuzilish doimiyligi hamda tashqi ko'rinishini saqlash imkonini beradi.

Kuchli kislotalar, tuzli suv yoki boshqa zararli moddalarga ta'sir qiluvchi sanoatlar ayniqsa po'lat naylarning korroziyaga chidamligidan foydalanadi. Bu xususiyat ularning xizmat ko'rsatish muddatini uzaytiradi va xarajatlarni kamaytiradi, shu sababli ham ular uzoq muddatli sanoat dasturlari uchun iqtisodiy jihatdan to'g'ri tanlovdir.

Po'lat naylar o'ta yuqori bosim va harorat sharoitida ham ularning konstruktiv mustahkamligini saqlab turadigan juda yuqori mexanik mustahkamlikka ega. Po'latning og'irlik-mustahkamlik nisbati sanoatning og'ir vazifalari hamda aniq boshqaruv talab etiladigan nozik jarayonlar uchun ham naylarni g'oya uygun qiladi.

Tuproqqa chidamli po'lat quvurlarning chidamliligi oddiy mexanik mustahkamlikdan ham yuqori. Ushbu quvurlar kriogen sharoitlardan boshlab yuqori haroratlargacha bo'lgan keng harorat diapazonida xususiyatlarini saqlaydi, bu esa ularni turli sanoat sohalarida qo'llash uchun mos qiladi. Bu ko'p jihatdan foydalanish imkonini beradi va turli jarayon sharoitlari uchun turli quvur materiallariga ehtiyoj qoldirmaydi.

Tuproqqa chidamli po'lat quvurlar barqaror sanoat amaliyotlariga sezilarli darajada hissa qo'shadi. Materialning o'zi 100% qayta ishlanadi va aksariyat tuproqqa chidamli po'lat quvurlar qayta ishlangan moddalarning yuqori foizini o'z ichiga oladi. Qayta ishlanish omili sanoat faoliyatining atrof-muhitga ta'sirini kamaytiradi va aylanma iqtisodiyot tashabbuslarini qo'llab-quvvatlaydi.

Borli temir quvurlarning uzoq xizmat muddati ularning atrof-muhit uchun xavfsizligini yanada oshiradi. Kamroq almashtirish talab qilinishi va kamroq chiqindi hosil qilinishi tufayli ushbu quvurlar sanoat korxonalari karbon izini kamaytirishda yordam beradi hamda ekologik jihatdan mas'ul operatsiyalarni saqlashga yordam beradi. Shuningdek, borli temir quvurlarning barqarorligi ishlab chiqarish hamda transportirovka ehtiyojini kamaytiradi, natijada energiya iste'moli pasayadi.

Borli temir quvurlarga dastlabki sarmoya kiritish boshqa materiallarga qaraganda yuqori bo'lishi mumkin, lekin uzoq muddatli iqtisodiy foydalar dastlabki xarajatlardan ancha yuqori. Uzoq xizmat muddati, minimal ta'mirlash ehtiyoji hamda kamroq almashtirilish chastotasi borli temir quvurlarni sanoat sohasida xarajatlarni tejash imkonini beruvchi tanlov qiladi.

Korrozion va mexanik shikastlanishga chidamlilik sanoat jarayonlarida kamroq to'xtovlarga olib keladi, natijada operatsion samaradorlik yaxshilanadi va to'xtab turish xarajatlari kamayadi. Shuningdek, po'lat quvurlarning xizmat muddati tugagandan keyin qayta ishlanadigan qoldiq qiymati yuqori bo'lib, materiallarni qayta tiklashning katta qiymatini ta'minlaydi.

Oziq-ovqat va ichimlik sanoatida gilozli po'lat quvurlar gigiyena va mahsulot sifatini saqlash uchun zarur. Gilozli po'latning poroz bo'lmagan sirti bakteriyalarning o'sishini oldini oladi va tozalash hamda dezinfektsiya jarayonlarini yanada samarali qiladi. Bu quvurlar oziq-ovqat darajasidagi materiallar uchun qat'iy me'yoriy talablarga javob beradi va bir xil mahsulot sifatini ta'minlaydi.

Tez-tez tozalash va sterilizatsiya jarayonlariga chidash qobiliyati tufayli gilozli po'lat quvurlar oziq-ovqatni qayta ishlash korxonalari uchun ayniqsa qimmatli hisoblanadi. Ularning silliq sirti mahsulotlarning to'planishini oldini oladi va ifloslanish xavfini kamaytiradi, bu esa oziq-ovqat xavfsizligi standartlarini saqlash uchun ideal echimdir.

Kimyoviy qayta ishlash sanoati mahsulotlarning tozaligini saqlash qobiliyati hamda korrozionga chidamli bo'lishi tufayli nerjanga nisbatan ko'proq rustsiz po'lat quvurlarga tayanadi. Ushbu quvurlar xavfli kimyoviy moddalarni, yuqori haroratlarni va turlicha bosim sharoitlarini osonlik bilan bartaraf etadi hamda xavfsiz va samarali material o'tkazishni ta'minlaydi.

Neft-kimyo sohasida rustsiz po'lat quvurlar qattiq ish sharoitlariga chidamli bo'lishi va strukturaviy butunligini saqlashi tufayli katta ahamiyat kasb etadi. Ichki hamda tashqi korroziyaga chidamliligi ularni turli neft mahsulotlari va kimyoviy moddalarni qayta ishlash uchun mos qiladi.

To'g'ri parvarishlanib, loyihalangan chegaralar doirasida foydalanilsa, sanoat dasturlarida rustsiz po'lat quvurlar 50 yil yoki undan ortiq xizmat qilishi mumkin. Haqiqiy xizmat muddati ish sharoitlari, atrof-muhit ta'siri hamda parvarishlash amaliyoti kabi omillarga bog'liq.

Ha, borli tsement naylar yuqori haroratli ilovalar uchun a'lodir. Foydalanilgan borli tsementning aniq darajasiga qaramay, ular -200°C dan +800°C gacha bo'lgan haroratlarda tuzilish butunligi va ishlash xususiyatlarini saqlab turadi.

Uzoq xizmat muddati, minimal ta'mirlash talablari va yuqori chidamlilik tufayli borli tsement naylar iqtisodiy jihatdan qulayroqdir. Dastlabki xarajatlar yuqori bo'lishi mumkin, lekin almashtirish ehtiyojining kamayishi, ta'mirlash xarajatlarining pastligi va ajoyib qayta ishlanuvchanlik ularni uzoq muddat davomida iqtisodiy jihatdan afzal qiladi.

Yangiliklar

Yangiliklar2025-01-03

2024-10-23

2024-11-15