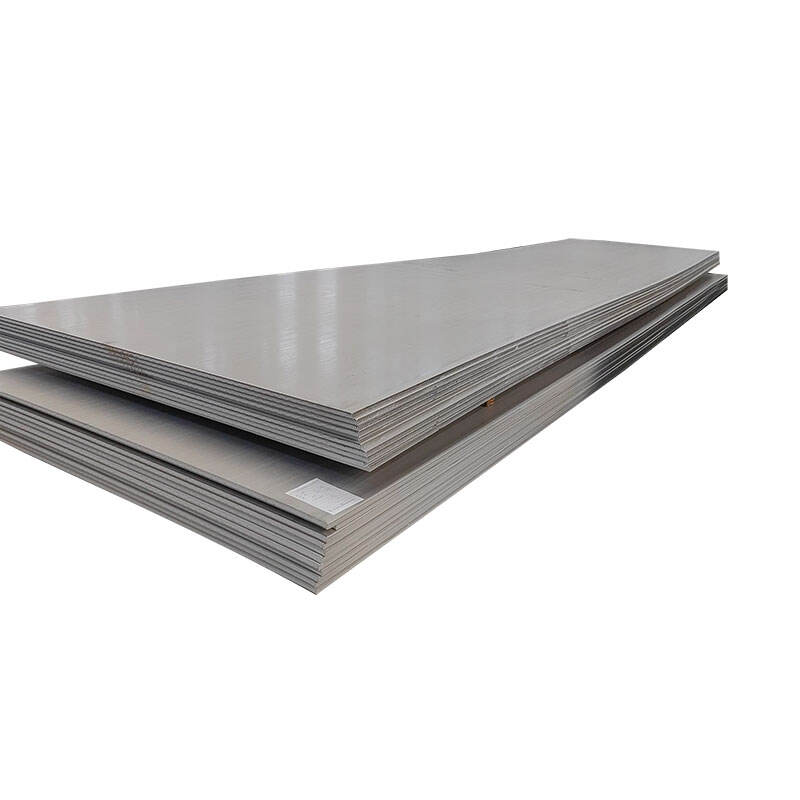

isidingo esilayishiwe ngomgqatelo we-stainless steel

Ikhoyili yesithalayamandla esikhulu esikhululwe kakhulu kuyinto ephumelela ngokusebenzisa indlela yekhoyili esikhulu, lapho isithalayamandla sikhululwe kakhulu ekhululweni kumqondo oqondile ukuthi siphumele ukuphela okuhle kakhulu nokuhlelela okuphezulu. Indlela yokwenza le nto iyahlukisa ukubinjwa kwekhoyili esikhulu esikhululwe kakhulu ngesikhathi esifanayo kuyahlola amaphaphu akhiyela nokuphela kwesayizi. Indlela yokuqina kuyindlela yokugcina ukuthi le nto iphumele ukuphakama okuphezulu, ukuvikela okuhle kakhulu nokuhlelela okuphezulu. Le khoyili inikezwa amagere amaningi, afakwe kahle, amaferritic, neemartensitic, nganye eneziphawo ezithile ezifanelela izimo ezahlukene. Isithalayamandla esikhulu esinekakhono yokukhawuleza, ngokudibanisa nokuvikela okuhle kakhulu, kuyinto engiyile kakhulu yezinto eziningi, kusukela kumoto nezokubanjwa kusukela kumoto nezokubanjwa, ukudla nokubulawa komhlaba nokwenza amagereyimende aphakeme. Indlela yokukhulula kakhulu iyageza ukuphela okuphezulu, okungaba yikhala elibonakalayo, kusukela kumakoti kuya kumakoti amaphethile, ngokwesicelo seziphumo.