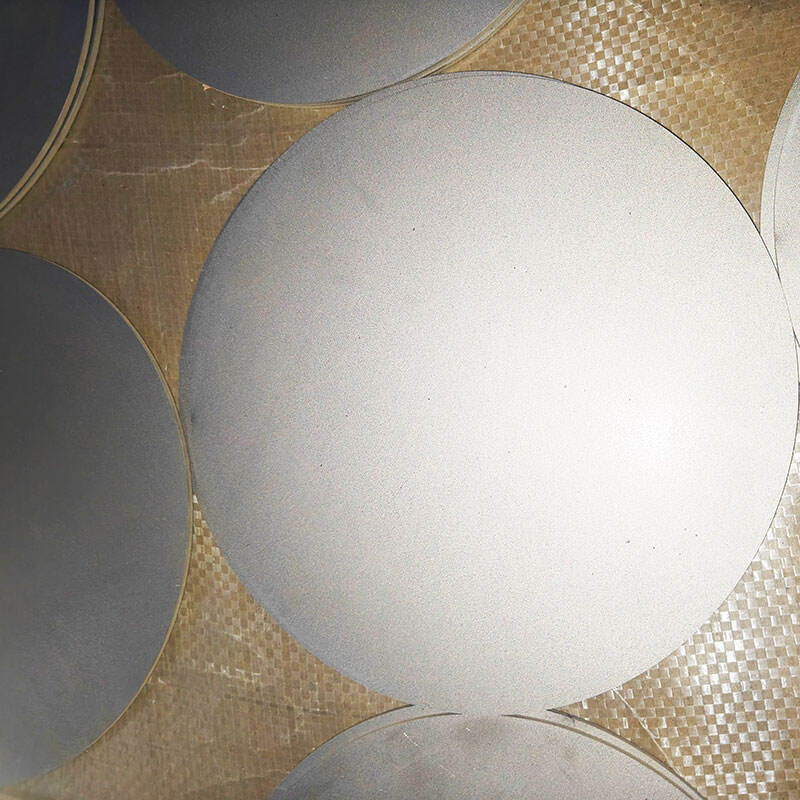

titaanblad

Titaniumplate verteenwoordig 'n hoëtepuntmateriaaloplossing wat uitstekende sterkte met opmerklike ligteienskappe kombineer. Hierdie veelvuldige metaalplate word vervaardig deur gevorderde metallurgiese prosesse, wat 'n produk lewer wat uitstekende korrosiebestandigheid vertoon en strukturele integriteit behou oor ekstreme temperatuurgebreke. Die plate is beskikbaar in verskeie grade en diktes, elk ontwerp om spesifieke bedryfsvereistes te voldoen. Wat titaniumplate uitstekend maak, is hul indrukwekkende sterkte-gewigverhouding, 45% ligter as staal terwyl dit vergelykbare sterkte-eienskappe behou. Die materiaal se natuurlike vermoë om 'n beskermende oksiedlaag te vorm, maak dit hoogs bestandig teen verskeie vorme van omgewingsdegradasie. In industriële toepassings word titaniumplate wyd gebruik in lugvaartkomponente, mediese implante, chemiese verwerkingsuitrusting en seeomgewings. Die materiaal se biokompatibiliteit en nie-toksiese aard maak dit veral waardevol in mediese en voedselverwerkingsbedrywe. Moderne vervaardigingstegnieke maak dit moontlik om presiese beheer oor die plaat se eienskappe te behou, insluitend oppervlakafwerking, dimensionele akkuraatheid en meganiese eienskappe. Hierdie plate kan maklik vervaardig word deur konvensionele metodes soos saamsmelting, vormgewing en masjineringswerk, alhoewel spesiale tegnieke soms benodig word as gevolg van die materiaal se unieke eienskappe.