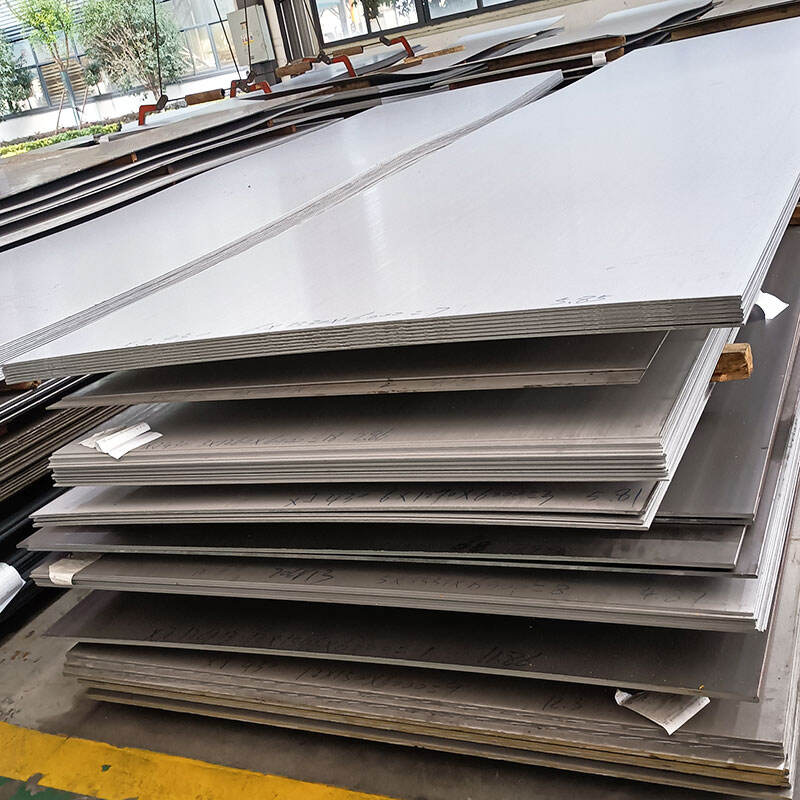

316l stainless steel sheet

316L stainless steel sheet stands as a premium-grade austenitic stainless steel material renowned for its exceptional corrosion resistance and versatile applications. This high-performance alloy contains low carbon content (0.03% maximum) and is enhanced with molybdenum, making it particularly resistant to pitting and crevice corrosion in aggressive environments. The material excels in marine applications, chemical processing, and medical equipment manufacturing due to its outstanding resistance to chlorides and acids. The 316L grade's low carbon variation prevents carbide precipitation during welding, ensuring maintained corrosion resistance in welded structures. These sheets are available in various surface finishes, from mirror-polished to matte, accommodating both functional and aesthetic requirements. The material's excellent formability allows for complex fabrication while maintaining structural integrity. With a working temperature range from cryogenic to 870°C, it serves diverse industrial needs. The non-magnetic properties and exceptional cleanability make it ideal for sterile environments, while its sustainable nature allows for 100% recyclability without loss of quality.