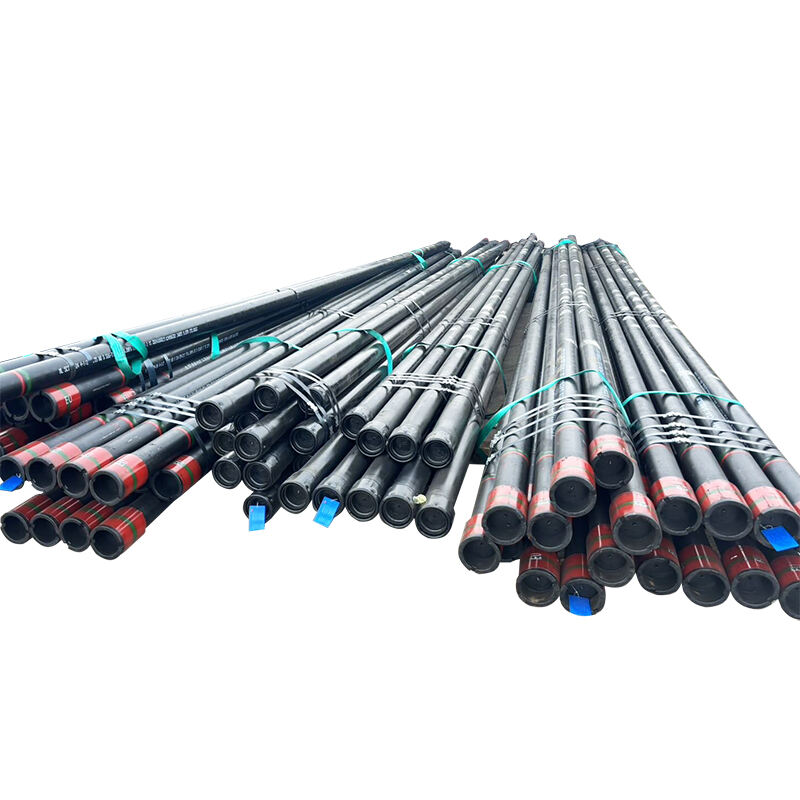

carbon steel pipe

Carbon steel pipe stands as a fundamental component in modern industrial infrastructure, characterized by its robust construction and versatile applications. These pipes are manufactured through a precise process that combines iron with carbon, typically containing between 0.05% to 2.1% carbon content, which significantly influences their strength and durability. The pipes feature a uniform composition throughout their structure, ensuring consistent performance under various operational conditions. They excel in high-temperature and high-pressure environments, making them ideal for fluid transportation systems, structural supports, and mechanical applications. Carbon steel pipes are available in various dimensions and wall thicknesses, accommodating different pressure ratings and installation requirements. Their manufacturing process includes hot rolling or cold drawing methods, followed by heat treatment procedures that enhance their mechanical properties. These pipes demonstrate exceptional resistance to mechanical stress, making them suitable for both underground and above-ground installations. The material's inherent properties allow for excellent weldability and machinability, facilitating easier installation and maintenance procedures. In industrial settings, carbon steel pipes are widely utilized in oil and gas transmission, water distribution systems, and chemical processing plants, where their reliability and strength are paramount.