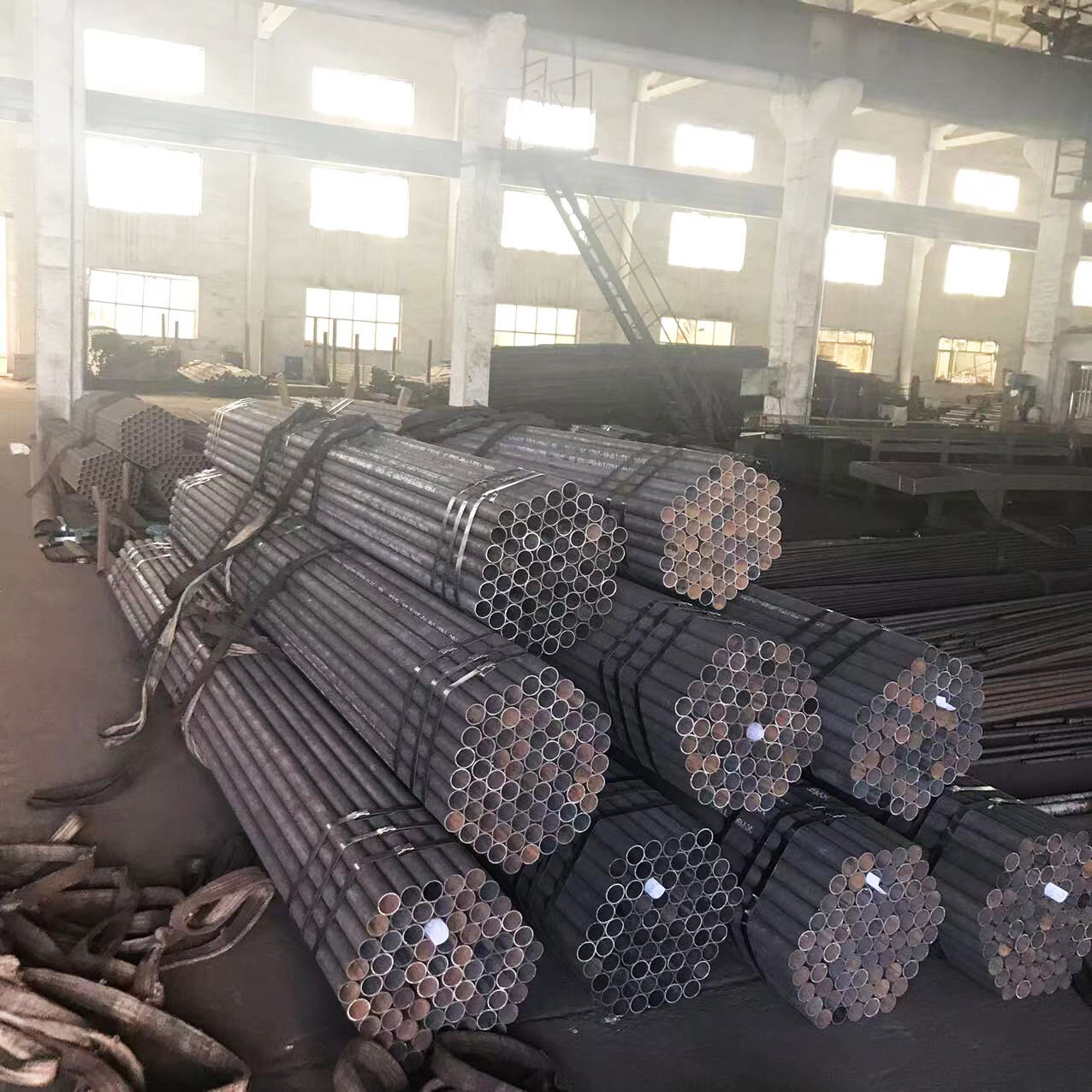

galvanized steel pipe

Galvanized steel pipe represents a crucial innovation in construction and industrial applications, featuring a protective zinc coating that significantly enhances its durability and longevity. This specialized coating process, known as galvanization, creates a robust barrier against corrosion and rust, effectively extending the pipe's service life. The manufacturing process involves immersing steel pipes in molten zinc at approximately 860 degrees Fahrenheit, ensuring complete coverage and protection. These pipes find extensive use in water distribution systems, fire sprinkler systems, and various industrial applications. Their versatility makes them ideal for both indoor and outdoor installations, capable of withstanding diverse environmental conditions. The zinc coating not only provides exceptional corrosion resistance but also offers self-healing properties, as any minor scratches are protected by the surrounding zinc coating. Modern galvanized steel pipes are manufactured to meet strict industry standards, ensuring consistent quality and reliability. They come in various diameters and wall thicknesses, making them suitable for different pressure requirements and applications. The combination of strength, durability, and cost-effectiveness has established galvanized steel pipes as a standard choice in construction and industrial sectors worldwide.