api 5l line pipe

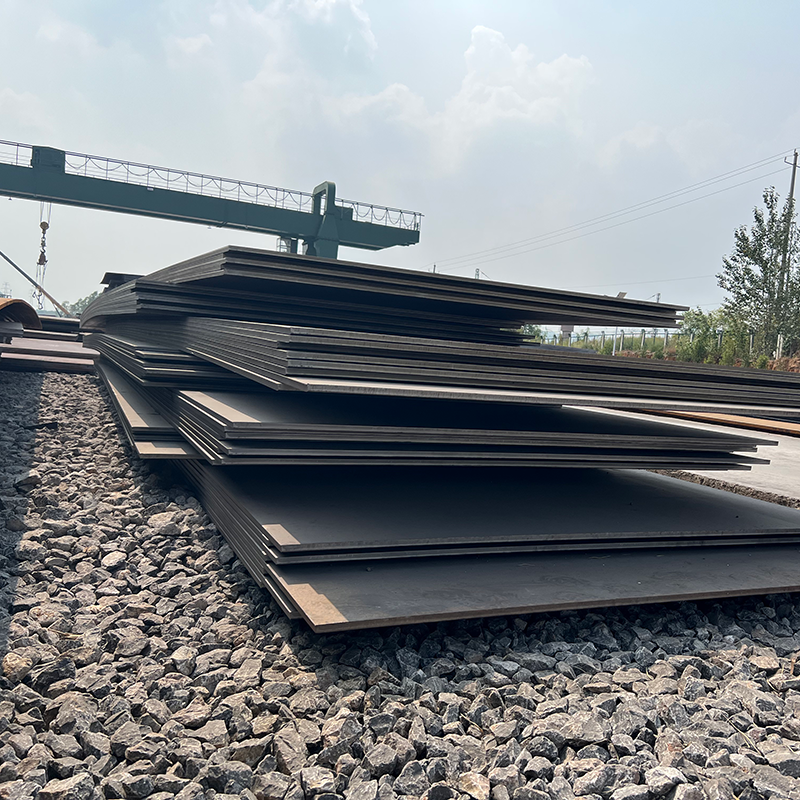

API 5L line pipe represents a crucial component in the oil and gas industry, manufactured according to the American Petroleum Institute's stringent specifications. These pipes are specifically designed for the transportation of oil, gas, and other petroleum products across vast distances under varying pressure conditions. The manufacturing process involves advanced steel forming techniques, ensuring superior structural integrity and resistance to environmental factors. API 5L pipes are available in various grades, including X42, X52, X60, and X70, each offering different yield strengths to meet specific operational requirements. The pipes undergo rigorous testing procedures, including hydrostatic testing, mechanical testing, and chemical composition analysis, to ensure compliance with international safety standards. A key technological feature is their seamless or welded construction, with both options providing specific advantages for different applications. The pipes are treated with specialized coatings to prevent corrosion and extend their operational lifespan. Their dimensional accuracy and consistent wall thickness contribute to reliable performance in high-pressure environments. These pipes find extensive applications in cross-country pipelines, gathering lines in oil fields, refineries, and petrochemical plants, making them an indispensable element in modern energy infrastructure.