copper sheet price

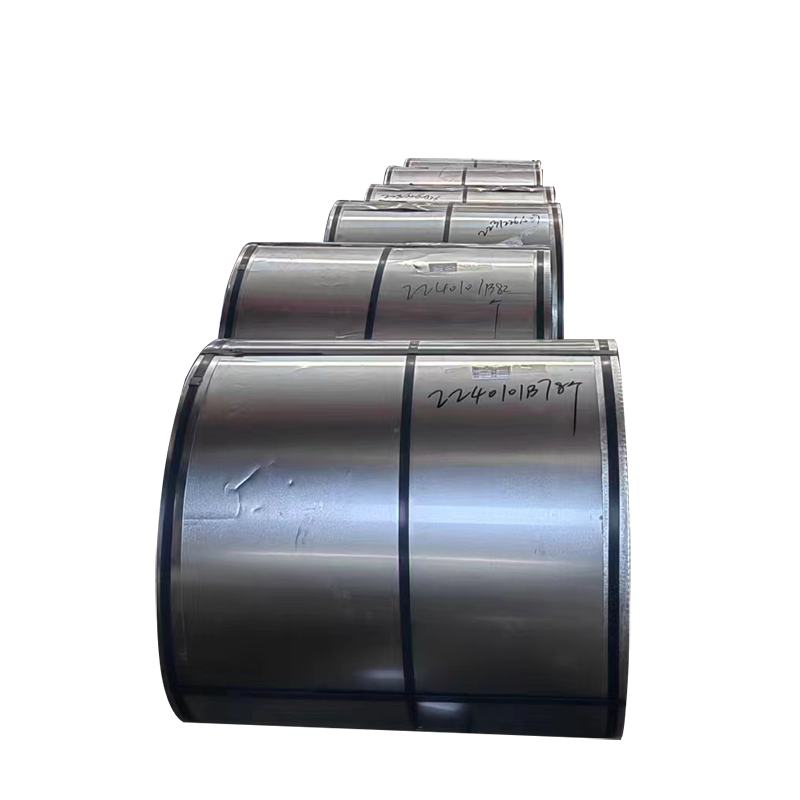

The copper sheet price reflects a dynamic market influenced by various factors, including global demand, manufacturing costs, and raw material availability. Copper sheets, essential components in numerous industries, are valued for their exceptional thermal and electrical conductivity, making them indispensable in electronics, construction, and industrial applications. The pricing structure typically considers factors such as thickness, grade, purity level, and surface finish. High-grade copper sheets, featuring 99.9% purity, command premium prices due to their superior performance characteristics. The market price fluctuates based on international copper commodity rates, production capacity, and regional demand-supply dynamics. These sheets are manufactured through precise rolling processes, ensuring uniform thickness and surface quality, which impacts the final pricing. Current market trends show varying prices across different regions, with factors like transportation costs, import duties, and local market conditions playing crucial roles in determining the final cost. The pricing also reflects the versatility of copper sheets in applications ranging from electrical components to architectural elements, making them a valuable investment for businesses across multiple sectors.