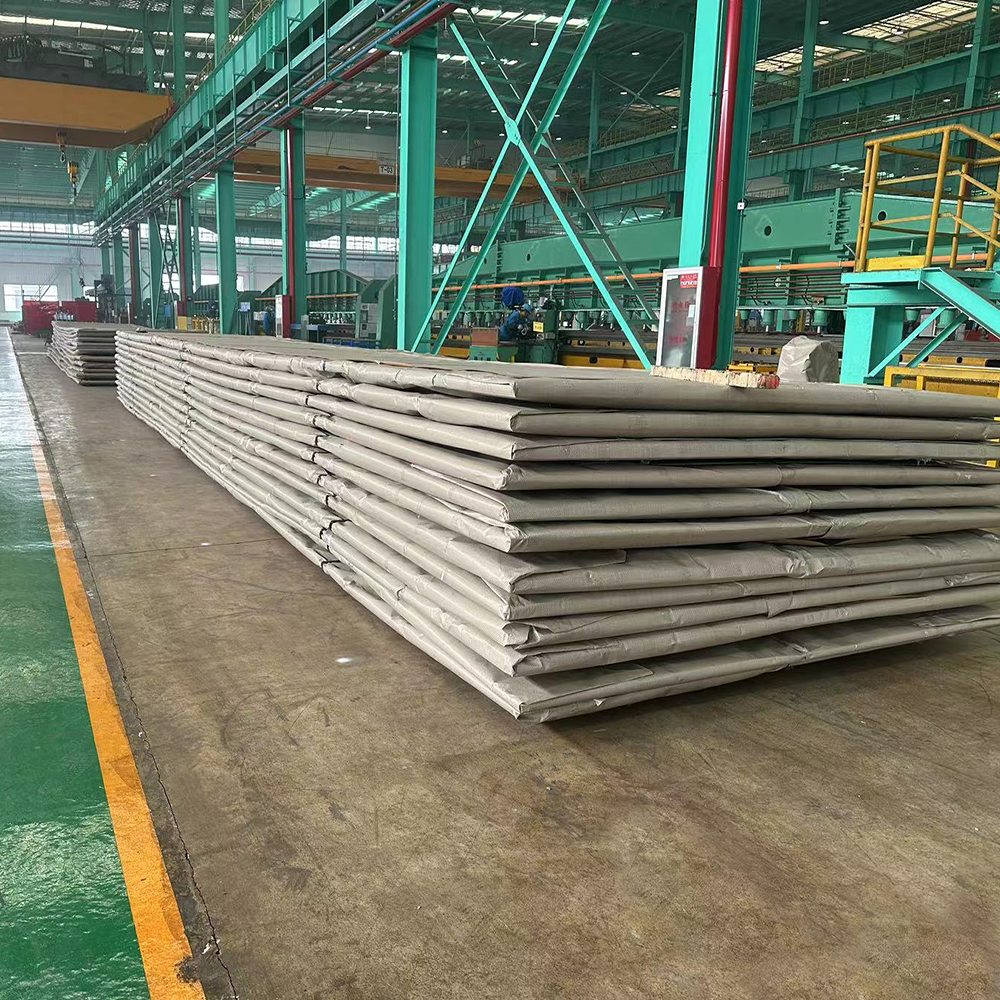

erw pipe

ERW (Electric Resistance Welded) pipe represents a crucial innovation in modern industrial piping solutions. This manufacturing process involves high-frequency electric resistance welding, where steel strips are continuously formed and welded into a tubular shape. The process begins with steel coils that are carefully shaped through a series of rollers, creating a uniform cylindrical form. The edges are then precisely heated using electromagnetic induction and pressed together to create a strong, seamless weld. ERW pipes are manufactured under stringent quality control measures, ensuring consistent wall thickness, precise dimensional accuracy, and superior weld integrity. These pipes typically range from 1/2 inch to 24 inches in diameter and can be produced in various wall thicknesses to meet specific industry requirements. The technology employs advanced automation and monitoring systems to maintain weld quality and structural integrity throughout the production process. ERW pipes are widely utilized across numerous sectors, including oil and gas transportation, construction, water supply systems, and structural applications. Their versatility makes them suitable for both high-pressure and low-pressure applications, while their uniform structure ensures reliable performance under various operating conditions.