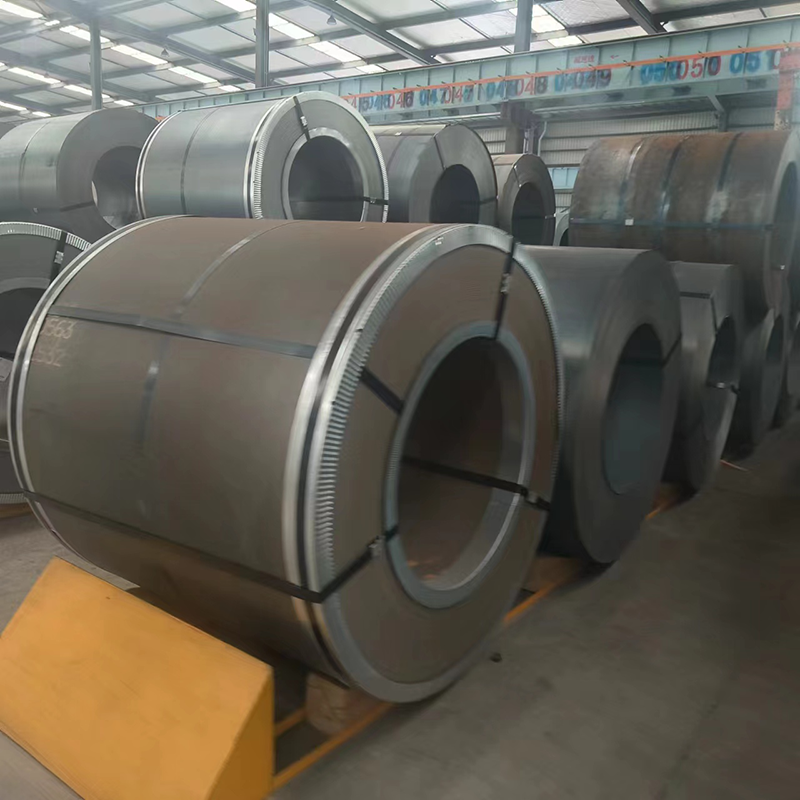

galvanized coil

A galvanized coil represents a sophisticated steel product that undergoes a specialized zinc coating process to enhance its durability and corrosion resistance. This engineered material consists of a steel base that's continuously passed through a bath of molten zinc, creating a metallurgically bonded protective layer. The resulting coating provides exceptional protection against rust and environmental degradation while maintaining the structural integrity of the base metal. The manufacturing process ensures uniform coating thickness and surface quality, making galvanized coils ideal for various applications across multiple industries. These coils are available in different thickness specifications and zinc coating weights, allowing for customization based on specific end-use requirements. The galvanization process not only provides superior corrosion protection but also offers self-healing properties at cut edges and scratches, where the zinc coating sacrificially protects the exposed steel. This material excels in both indoor and outdoor applications, offering reliable performance in diverse environmental conditions. The versatility of galvanized coils makes them an essential component in construction, automotive manufacturing, and industrial applications, where long-term durability and cost-effectiveness are paramount considerations.