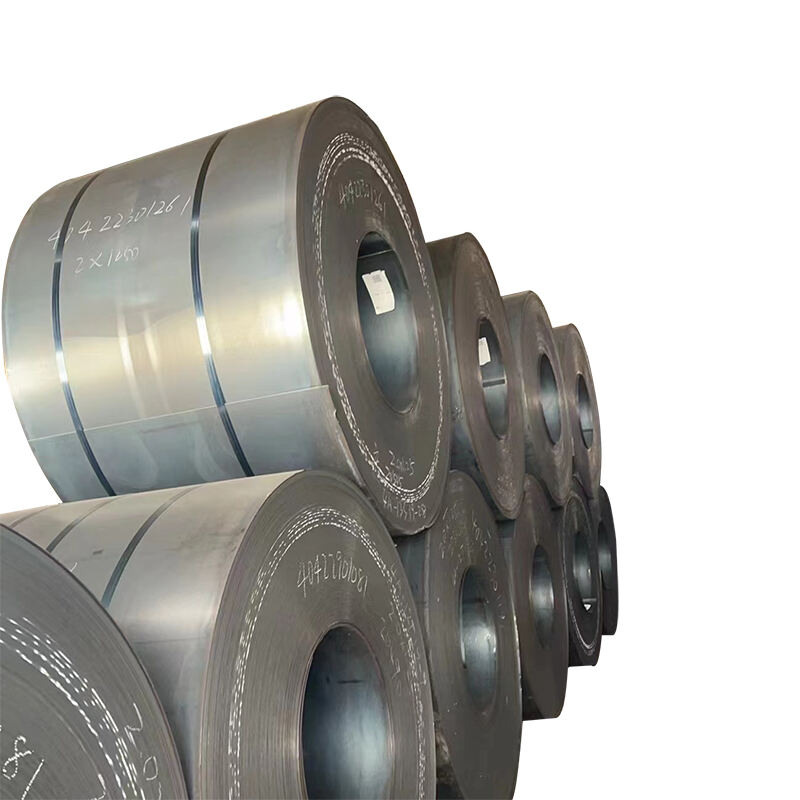

ppgi coil

PPGI coil, also known as Pre-painted Galvanized Iron coil, represents a significant advancement in metal construction materials. This innovative product consists of a steel substrate that undergoes hot-dip galvanization and is then coated with a specialized paint system. The manufacturing process involves careful surface preparation, primer application, and a final color coating that ensures both aesthetic appeal and durability. These coils typically feature multiple layers, including a zinc coating for corrosion resistance, a primer for enhanced adhesion, and a top coat that provides the desired color and weather resistance. PPGI coils are engineered to withstand various environmental conditions, offering excellent resistance to UV radiation, moisture, and chemical exposure. The material's versatility makes it ideal for numerous applications, from roofing and wall cladding to industrial equipment and household appliances. The standardized production process ensures consistent quality and uniform appearance across large surface areas. Additionally, PPGI coils are available in various thicknesses, widths, and color options, allowing for customization according to specific project requirements. The material's structural integrity, combined with its decorative properties, makes it a preferred choice in modern construction and manufacturing sectors.