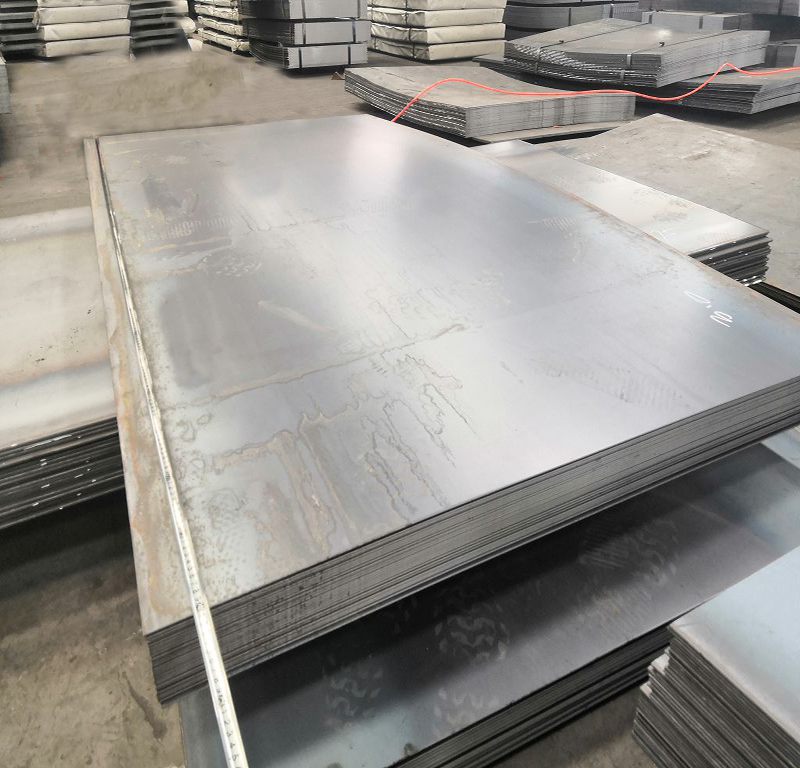

stainless 316 sheet

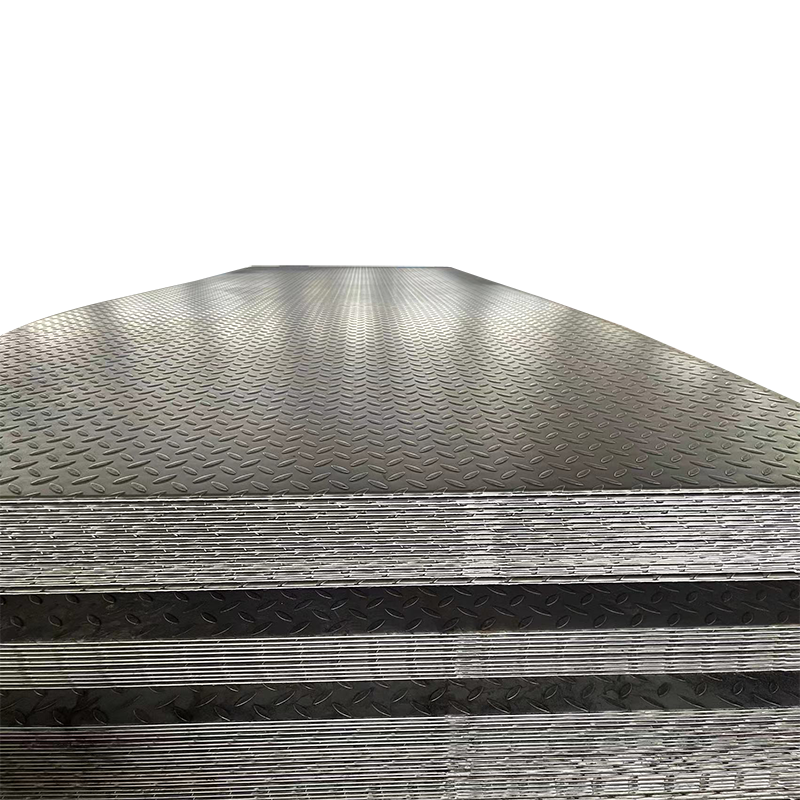

Stainless 316 sheet represents a premium grade austenitic stainless steel that offers exceptional corrosion resistance and durability. This versatile material contains a carefully balanced composition of chromium, nickel, and molybdenum, making it particularly resistant to chlorides and harsh industrial chemicals. The addition of molybdenum enhances its pitting and crevice corrosion resistance, especially in marine environments. The material maintains its structural integrity across a wide temperature range, from cryogenic conditions to elevated temperatures up to 870°C. Stainless 316 sheet exhibits excellent formability and weldability, making it suitable for various fabrication processes. Its non-magnetic properties and low carbon content prevent sensitization during welding. The material's smooth surface finish not only provides aesthetic appeal but also enhances its hygienic properties, making it ideal for applications in food processing, pharmaceutical manufacturing, and medical equipment. The sheet's mechanical properties include high tensile strength, good ductility, and impressive impact resistance, ensuring long-term reliability in demanding applications. These characteristics make it a preferred choice in marine environments, chemical processing plants, architectural applications, and various industrial settings where superior corrosion resistance and strength are essential.