stainless steel tube stockist

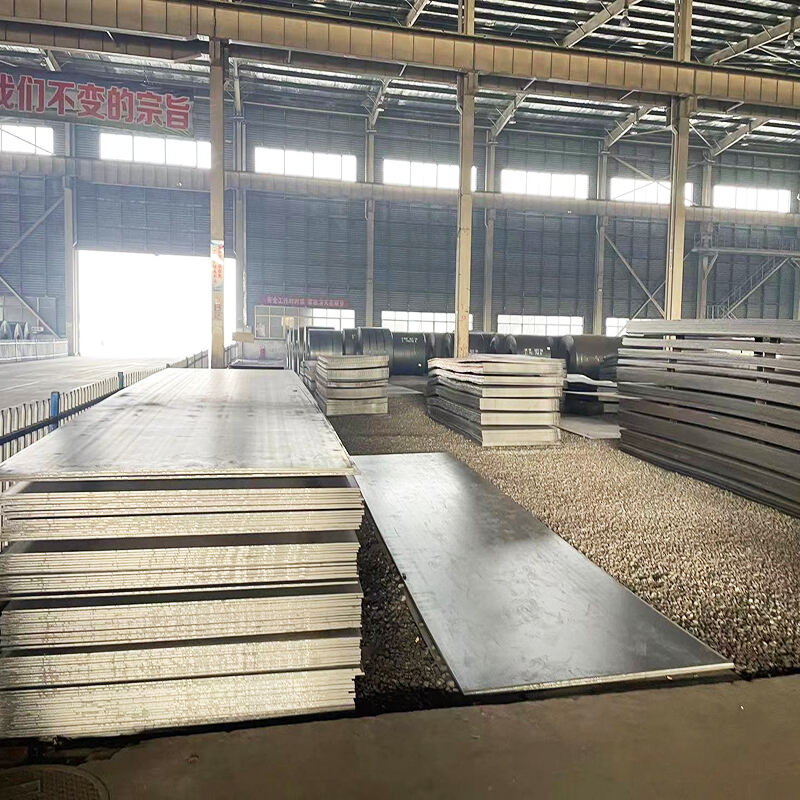

A stainless steel tube stockist serves as a vital link in the industrial supply chain, maintaining comprehensive inventories of high-quality stainless steel tubing in various grades, sizes, and specifications. These specialized suppliers ensure immediate availability of essential materials for manufacturers, construction companies, and engineering firms. Modern stockists utilize advanced inventory management systems to track stock levels, monitor product specifications, and ensure optimal storage conditions. They typically maintain climate-controlled warehouses to prevent corrosion and maintain material integrity. Professional stockists offer value-added services including custom cutting, specialized packaging, material certification, and technical consultation. Their expertise extends to various grades of stainless steel, including popular options like 304, 316, and 321, each suited for specific applications. They play a crucial role in supporting industries such as chemical processing, food and beverage manufacturing, pharmaceutical production, and architectural applications. The most reputable stockists maintain relationships with leading mills worldwide, ensuring consistent quality and competitive pricing. Their quality control processes include regular material testing, certification verification, and proper handling procedures to maintain product integrity.