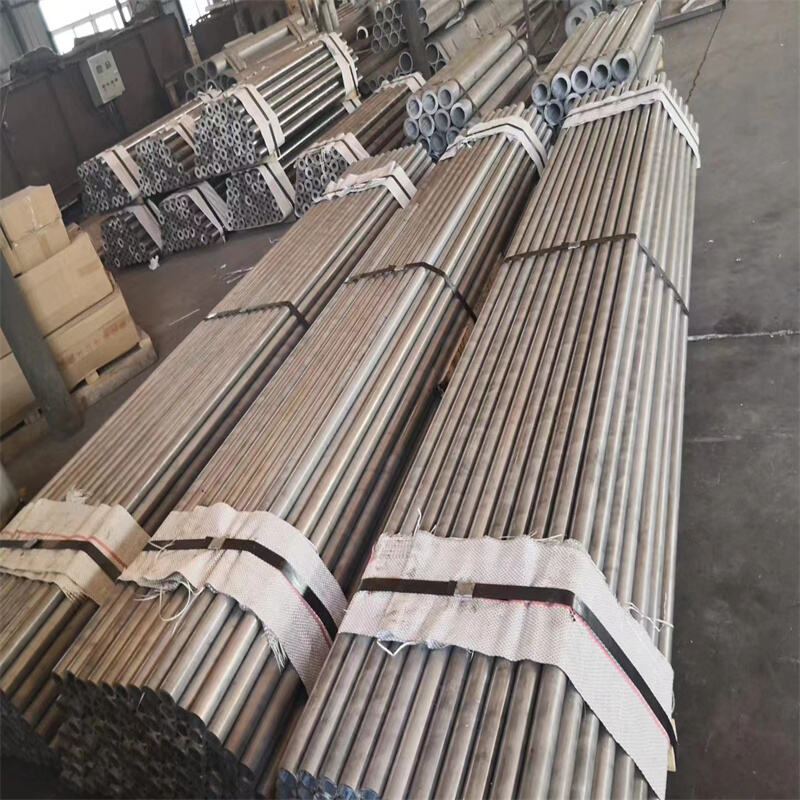

2205 dairəvi bar

2205 dairəvi profil yüksək keyfiyyətli dubl döşəməli növ paslanmayan polad məhsuludur ki, o, yüksək möhkəmlik və yaxşı korroziyaya davamlılığı birləşdirir. Bu çox yönlü material təxminən eyni miqdarda avstenit və ferit fazalarından ibarətdir və bu da yüksək mexaniki xassələrə malik olan unikal mikrostruktur yaradır. Tərkibində 22% xrom və 5% nikel olan 2205 markası davamlılıq və performans baxımından optimal balans təmin edir. Bu dairəvi profillər dəqiq isti yuvarlama və istilik müalicəsi prosesləri ilə istehsal olunur və beləliklə materialın daxilində keyfiyyətin sabit qalmasını təmin edir. Məhsul xüsusilə dəniz tətbiqlərində, kimyəvi emal zavodlarında və neft və qaz sənayesində kimi çətin şəraitdə istifadəyə uyğundur. Onun yüksək akstivlik həddi, adətən standart avstenit markalarının iki misli qədərdir və bu da həm möhkəmlik, həm də korroziyaya davamlılıq tələb olunan konstruksiyalarda istifadəsi üçün ideal seçimdir. Material pitting, qopma korroziyası və gərginlik korroziya çatlamasına qarşı yüksək müqavimət göstərir və yaxşı qaynaqlanma və emal edilmə xassələrini saxlayır. Müxtəlif diametrlərdə və uzunluqlarda mövcud olan 2205 dairəvi profillər müəyyən layihə tələblərinə cavab vermək üçün fərdi sifarişlərlə hazırlanabilir və bu da onları çətin tətbiqlərdə işləyən mühəndislər və konstruktorlar üçün çox yönlü seçim edir.