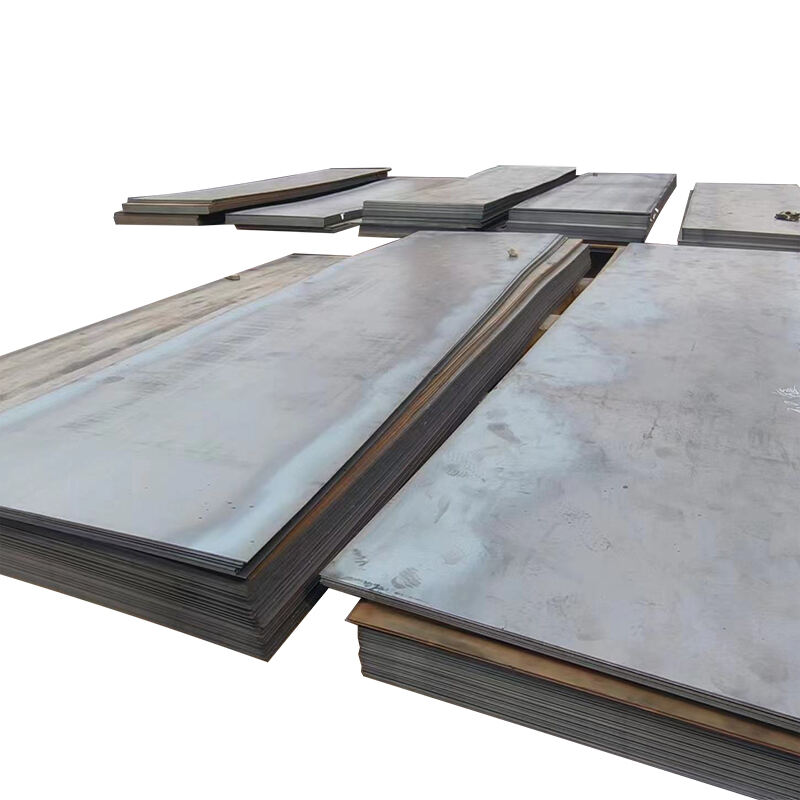

full d'acer galvanitzat

La xapa d'acer galvanitzat representa una innovació crucial en la tecnologia de protecció dels metalls, combinant durabilitat i versatilitat en la construcció i fabricació modernes. Aquest material especialitzat consisteix en una base d'acer recoberta amb una capa protectora de zinc mitjançant un procés de galvanització per immersió en calent. La capa de zinc crea una barrera sacrificable que protegeix activament l'acer subjacent contra la corrosió, augmentant significativament la vida útil del material. El procés de galvanització implica submergir xapes d'acer netes en zinc fos a una temperatura d'uns 860°F (460°C), resultant en un enllaç metal·lúrgic que forma diverses capes d'aliatge de zinc i ferro. Aquestes xapes solen presentar un patró d'estellets distintiu a la superfície, que pot variar des de mínim fins a molt visible depenent del procés específic de fabricació. L'gruix del material pot variar des de xapes fines adequades per a sostres fins a planxes resistents per a aplicacions industrials. En termes de funcionalitat, les xapes d'acer galvanitzat ofereixen una resistència excepcional a l'exposició meteorològica, als danys mecànics i a la corrosió química, fet que les fa ideals tant per a aplicacions interiors com exteriors. El material manté les seves propietats protectores fins i tot quan es talla o es perfora, ja que la capa de zinc continua protegint els extrems exposats mitjançant l'acció galvànica.