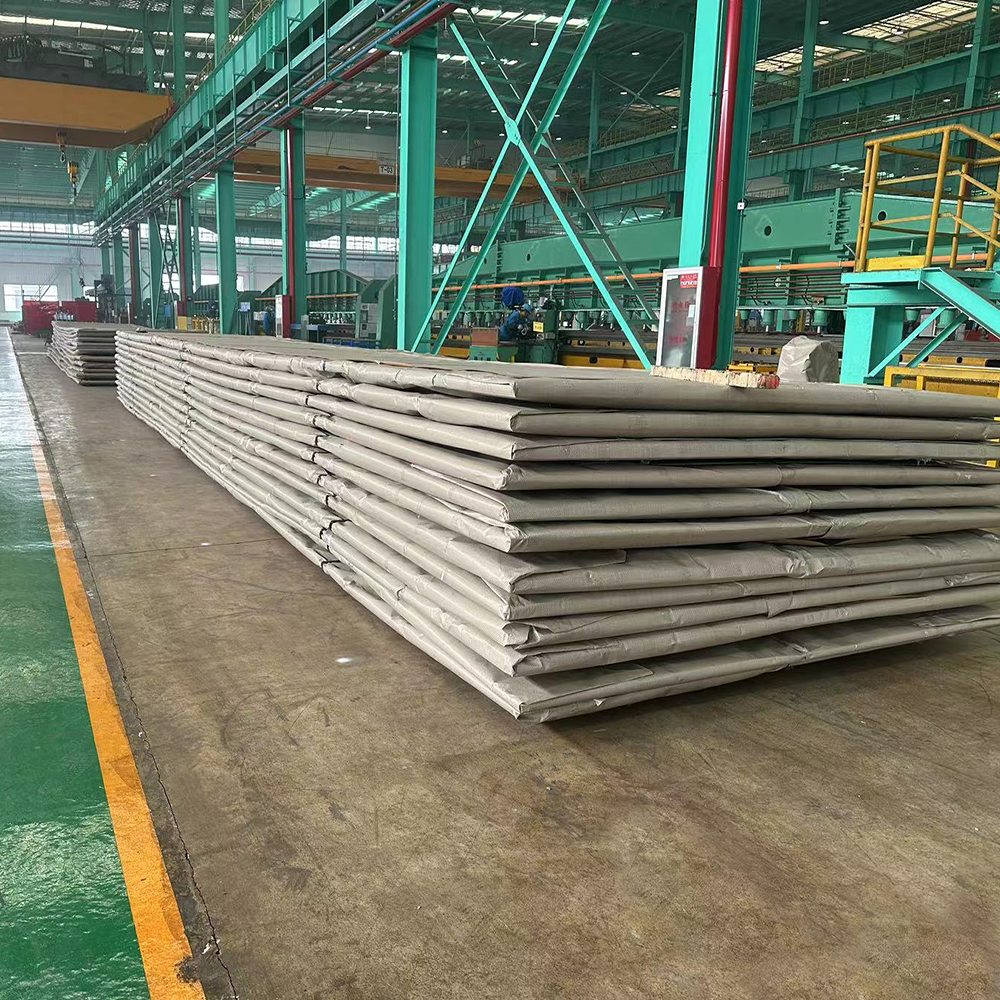

erw pipe

Hariarekin erresistentzia elektrikoaren bidez soldatutako (ERW) hodiak gaur egungo industria-hoditerako soluzio garrantzitsu bat da. Fabrikatzeko prozesu honek maiztasun altuko soldadura elektrikoaren bidezko erresistentzia erabiltzen du, non altzairuzko tira etengabe formatu eta soldatu egiten diren hodi itxura batean. Prozesua altzairuzko bobinetan hasten da, zehazki formaturiko zilindro uniforme bat lortzeko, hainbat erreolan zehar moldatuz. Ondoren, ertzak indukzio elektromagnetikoaren bidez berotzen dira zehazki eta elkarren kontra presionatzen dira soldadura sendoa eta jarraia lortzeko. ERW hodiak kalitate-kontrol gogorren bidez fabrikatzen dira, hormaren lodiera uniformea, neurri zehaztasuna eta soldadura-integritate altua bermatuz. Hodi hauek normalean 1/2 hazbetetik 24 hazbetera bitarteko diametroa dute eta hormaren lodiera ezberdinetan egin daitezke sektore jakin baten beharrak asetzeko. Teknologiak automatizazio eta gainbegiratze sistemak erabiltzen ditu soldadura kalitatea eta egitura-osotasuna mantentzeko ekoizpen prozesuan zehar. ERW hodiak sektore anitzetan erabiltzen dira, besteak beste, petrolio eta gasaren garraiorako, eraikuntzan, ur-hornidura sistemak eta aplikazio egiturazkoetan. Haien aldaezintasunak bihurketa horiek aplikazio presio altuko eta presio baxukoetan erabiltzeko egokiak izaten ditu, haien egitura uniformeak baldintza ezberdinetan errendimendu fidagarria bermatuz.