چرا مدارهای فولاد ریز اسان برای پروژههای صنعتی مقاوم به خوردگی ضروری هستند

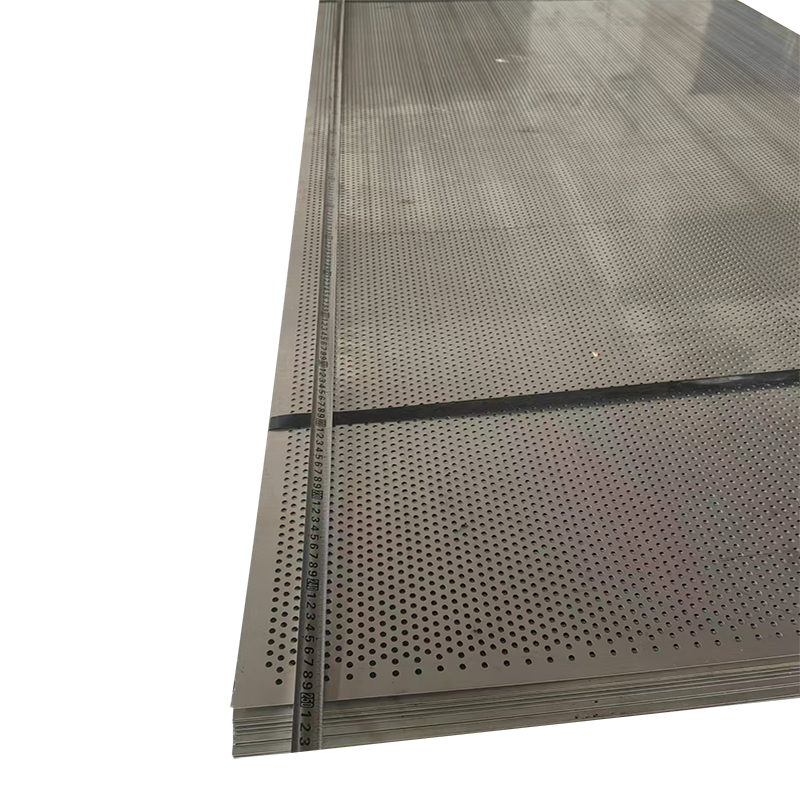

کاوش کنید در مورد مقاومت عالی خوردگی و طولانی بودن فولاد ریزش ناپذیر، ماده کلیدی در کاربردهای صنعتی مانند لولههای نفت و گاز، سیستمهای پردازش غذا و ساخت و ساز. آشنایی با قدرت مقاومت در دمای بالا و مزایای اقتصادی آن در کاهش فراوانی جایگزینی و نیاز به نگهداری.

مشاهده بیشتر