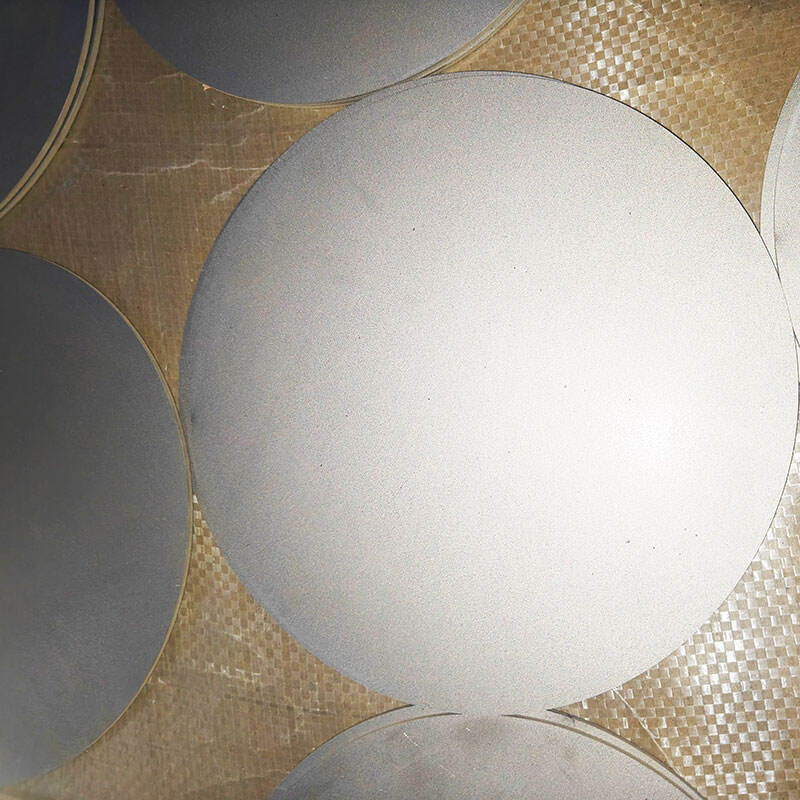

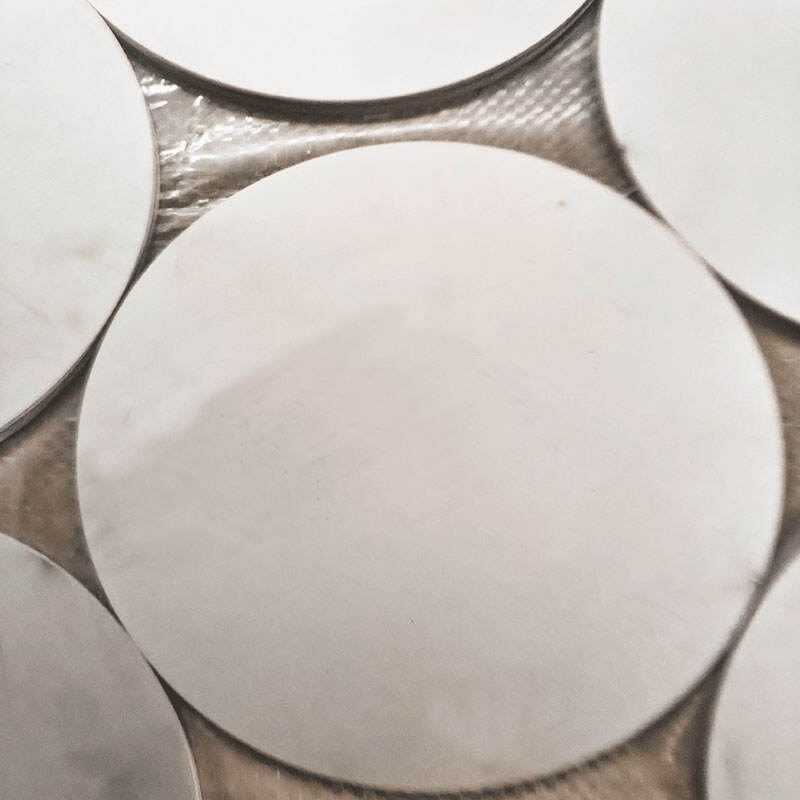

برگ آلیاژ تیتانیوم

ورقهای آلیاژی تیتانیوم نمادی از دستاوردهای مهندسی متالورژیکی مدرن هستند که ترکیبی استثنایی از استحکام بالا و وزن بسیار کم را فراهم میکنند. این مواد پیشرفته از طریق فرآیندهای دقیق آلیاژسازی تولید میشوند، جایی که تیتانیوم با عناصری مانند آلومینیوم، وانادیوم و مولیبدن ترکیب میگردد تا خواص ذاتی آن بهبود یابد. ورقهای حاصل دارای مقاومت برجسته در برابر خوردگی در شرایط محیطی متنوعی هستند و استحکام ساختاری خود را در کاربردهای دریایی و فرآوری مواد شیمیایی حفظ میکنند. نسبت استحکام به وزن بالای آنها، این ماده را بهویژه در صنایع هوافضا و خودروسازی بسیار ارزشمند کرده است، جایی که کاهش وزن نقش کلیدی در عملکرد و بهرهوری دارد. این ورقها مقاومت بسیار خوبی در برابر دماها نشان میدهند و خواص مکانیکی خود را از دمای کریوژنیک تا 600 درجه سانتیگراد حفظ میکنند. زیستسازگاری این ماده انقلابی در فناوری ایمپلنتهای پزشکی ایجاد کرده است، در حالی که جذابیت ظاهری آن منجر به استفادهاش در کاربردهای معماری شده است. تکنیکهای مدرن تولید کنترل دقیق بر روی ضخامت ورزع و سطح پرداخت سطح را فراهم میکنند و امکان سفارشیسازی را برای کاربردهای خاص فراهم میکنند. این ورقها همچنین مقاومت بسیار خوبی در برابر خستگی و گسترش ترک نشان میدهند و این اطمینان را فراهم میکنند که در کاربردهای با تنش بالا دارای قابلیت اطمینان بلندمدت باشند.