tube de gaine

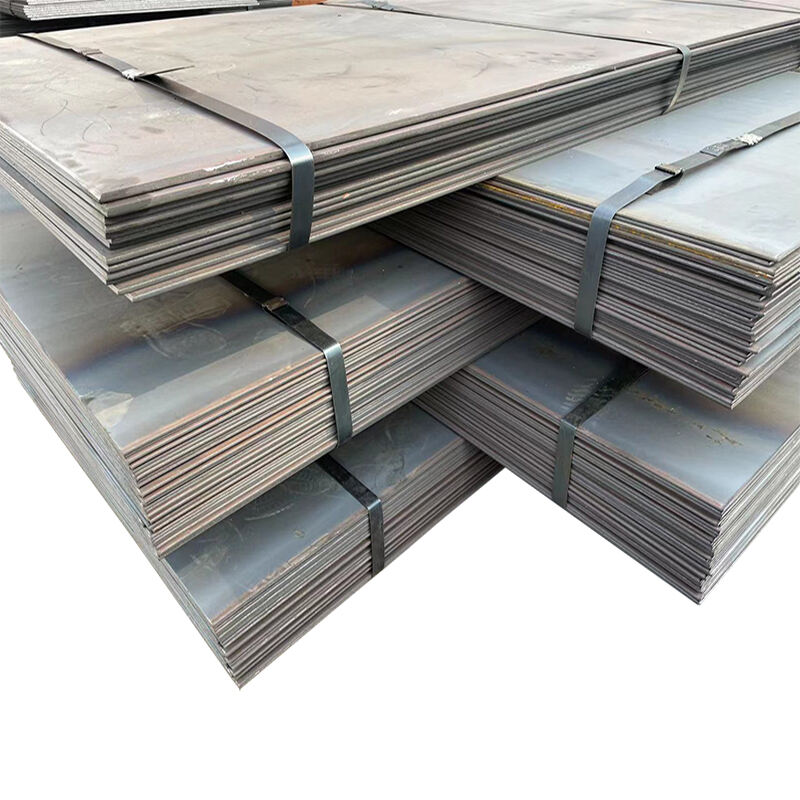

Un tube de cuvelage est un composant essentiel dans la construction de puits et les opérations de forage, il sert de barrière protectrice entre le trou de forage et les formations environnantes. Cette pièce vitale remplit plusieurs fonctions, notamment empêcher l'effondrement des formations, isoler différentes zones et protéger les ressources en eau souterraine. Le tube est généralement fabriqué en acier de haute qualité et se décline en différentes tailles et spécifications pour répondre à diverses exigences opérationnelles. Les tubes de cuvelage modernes intègrent des technologies métallurgiques avancées afin d'augmenter leur durabilité et leur résistance aux environnements corrosifs. Ils disposent de systèmes filetés précis garantissant des connexions sécurisées et préservant l'intégrité structurelle sous des conditions extrêmes de pression et de température. L'utilisation des tubes de cuvelage s'étend à divers secteurs, allant de l'exploration pétrolière et gazière aux puits géothermiques et aux systèmes de gestion de l'eau. Ils jouent un rôle fondamental dans le maintien de la stabilité du trou de forage tout au long du cycle opérationnel complet, du forage à la production, et jusqu'à l'abandon final. La conception des tubes de cuvelage prend en compte des facteurs tels que la pression des formations, les variations de température et la compatibilité chimique, les rendant essentiels pour des opérations de forage sûres et efficaces.