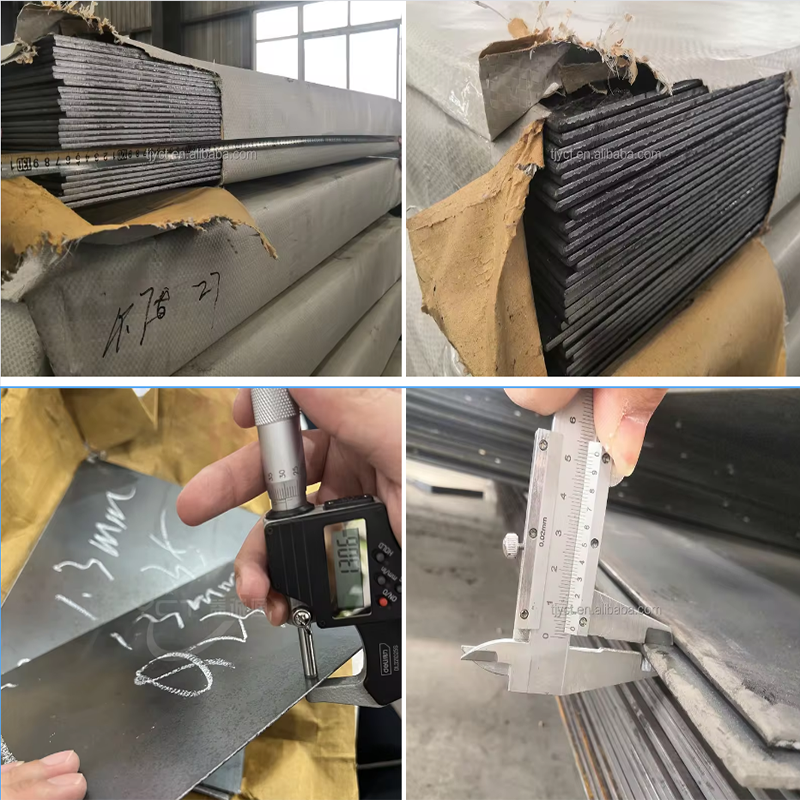

冷冷轧 Coil

Սառը գլանաձև կոճապարույրը ներկայացնում է բարձրակարգ պողպատե ապրանք, որն արտադրվում է մասնագիտացված գործընթացով, որտեղ տաք գլանաձև պողպատը հետագայում մշակվում է սենյակի ջերմաստիճանում: Այս առաջադեմ արտադրական տեխնիկան ապահովում է պողպատի ճշգրիտ հարմարեցման հնարավորություն, բարելավված մակերեսի վերջավորություն և բարելավված մեխանիկական հատկություններ: Գործընթացը ներառում է պողպատի անցումը մի շարք գլանների միջով սենյակի ջերմաստիճանում, որն աստիճանաբար նվազեցնում է դրա հաստությունը՝ բարելավելով չափական ճշգրտությունը և մակերեսի հատկությունները: Սառը գլանաձև կոճապարույրներն ունեն արտահայտված հարթություն, ճշգրիտ հաստության վերահսկում, սովորաբար 0.001 դյույմի սահմաններում, և հարթ, փայլուն մակերեսի վերջավորություն: Այս հատկությունները դրանք դարձնում են իդեալական ընտրություն բարձր ճշգրտություն և էսթետիկ տեսք պահանջող կիրառումների համար: Նյութն ունի մեծացած ամրություն և կոշտություն տաք գլանաձև տարբերակների համեմատ, շնորհիվ աշխատանքային կոշտացմանը, որն առաջանում է սառը գլանաձև գործընթացի ընթացքում: Հաճախ օգտագործվող կիրառումների օրինակներ են ավտոմեքենայի մարմնի սալերը, սարքերի կողականները, մետաղե կահույքը և տարբեր շինարարական բաղադրիչները: Վերահսկվող մշակման միջավայրն ապահովում է համապարփակ որակի համապարփակություն կոճապարույրի ամբողջ երկարությամբ, դրան դարձնելով հատկապես հարմար ավտոմատացված արտադրական գործընթացների համար: Բացի այդ, սառը գլանաձև կոճապարույրներն ապահովում են հիանալի ձևավորման և էլեկտրական լավ լցման հնարավորություններ, որոնք կարևոր բնութագծեր են բարդ ձևավորման գործընթացներ կամ հավաքման ընթացք պահանջող արդյունաբերությունների համար: